44 short path distillation diagram

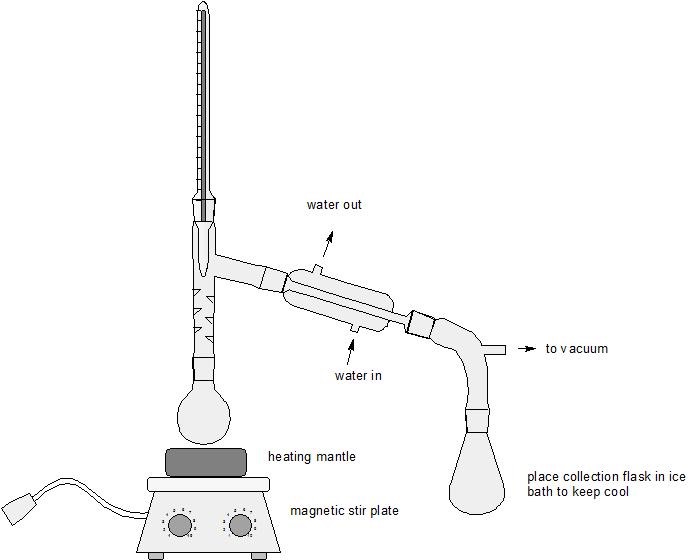

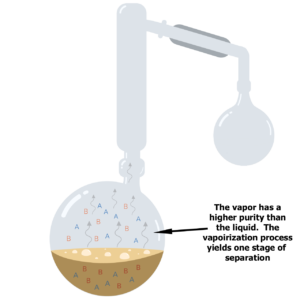

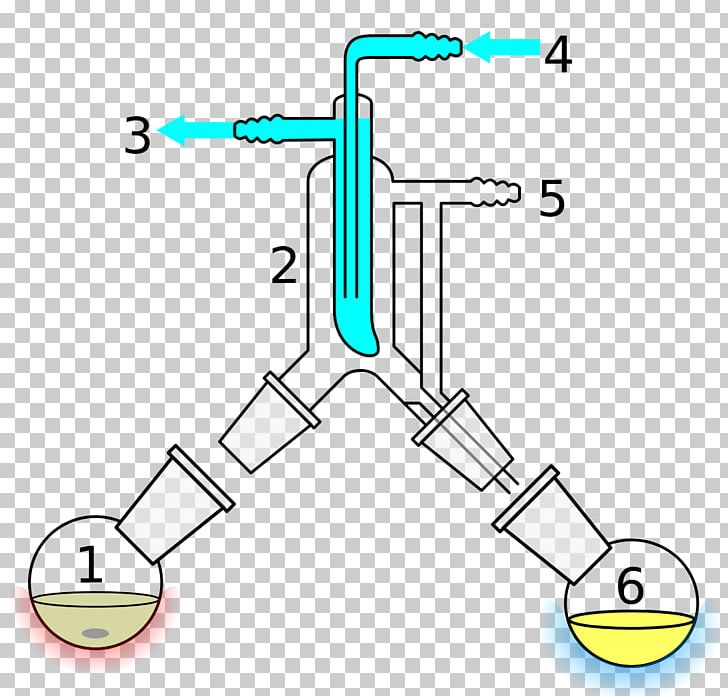

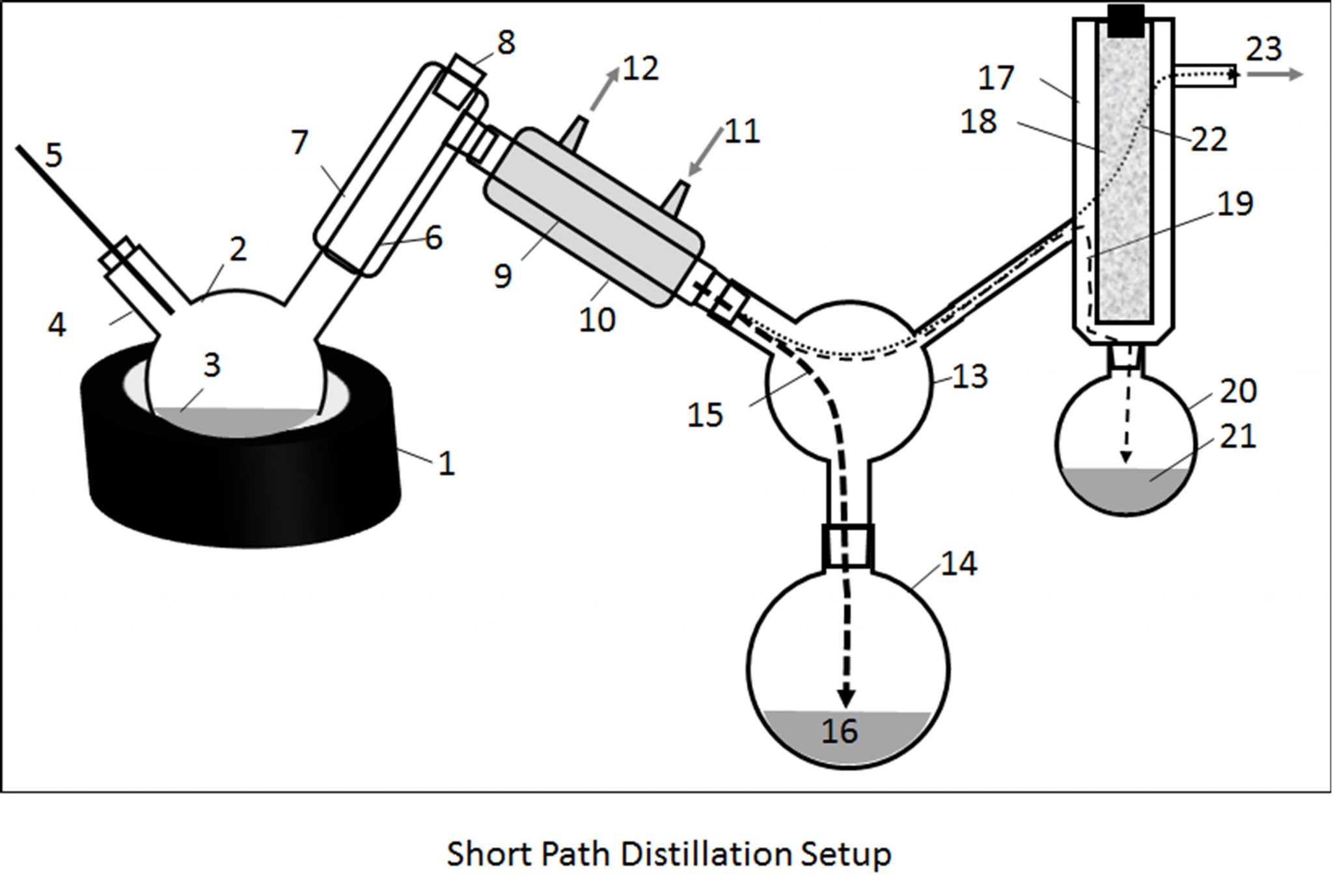

10.08.2021 · If they differ in their boiling points by 25°C or more, the separation can be done by simple distillation. If the difference is less than 25°C, fractional distillation is used. Acetone (b.p. = 56°C) and water (b.p. = 100°C) can be separated by simple distillation. For the labelled diagram, The Short Path Distillation Process. The short path distillation process employs a setup that uses the same principles, just without the wiper system to distribute the extraction material. Instead, a heated flask is where the extraction material is fed. Gradually, increased heat is applied to the extract material in the feed flask.

07.11.2021 · Graph analysis questions

Short path distillation diagram

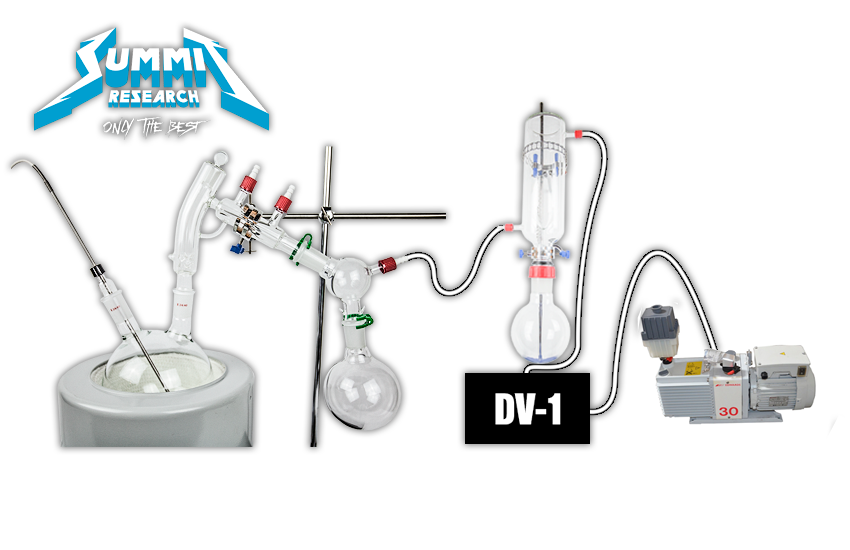

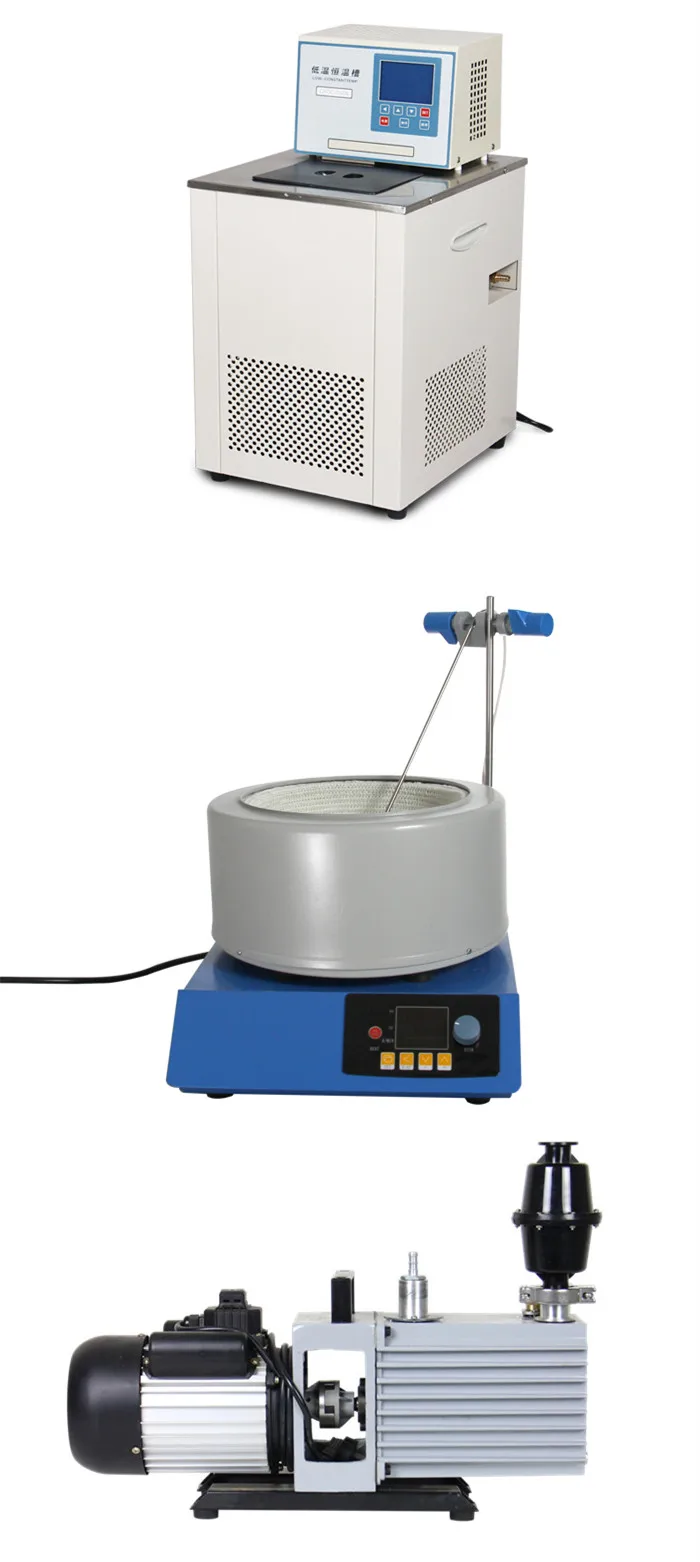

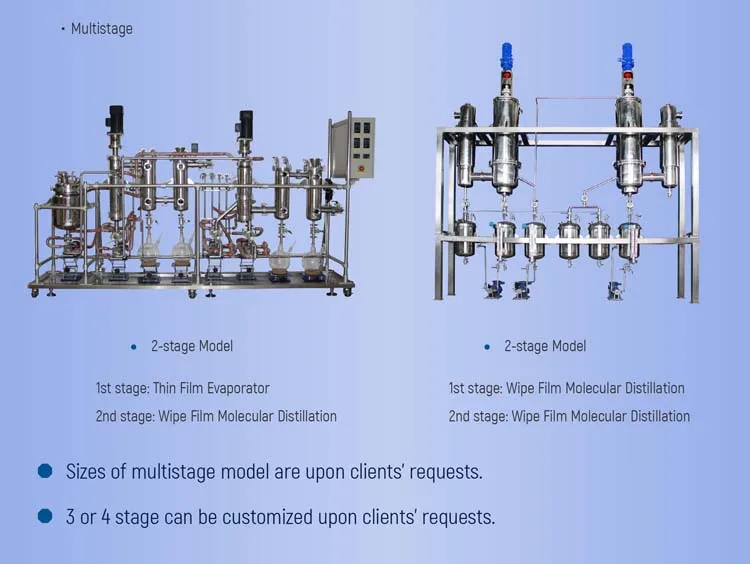

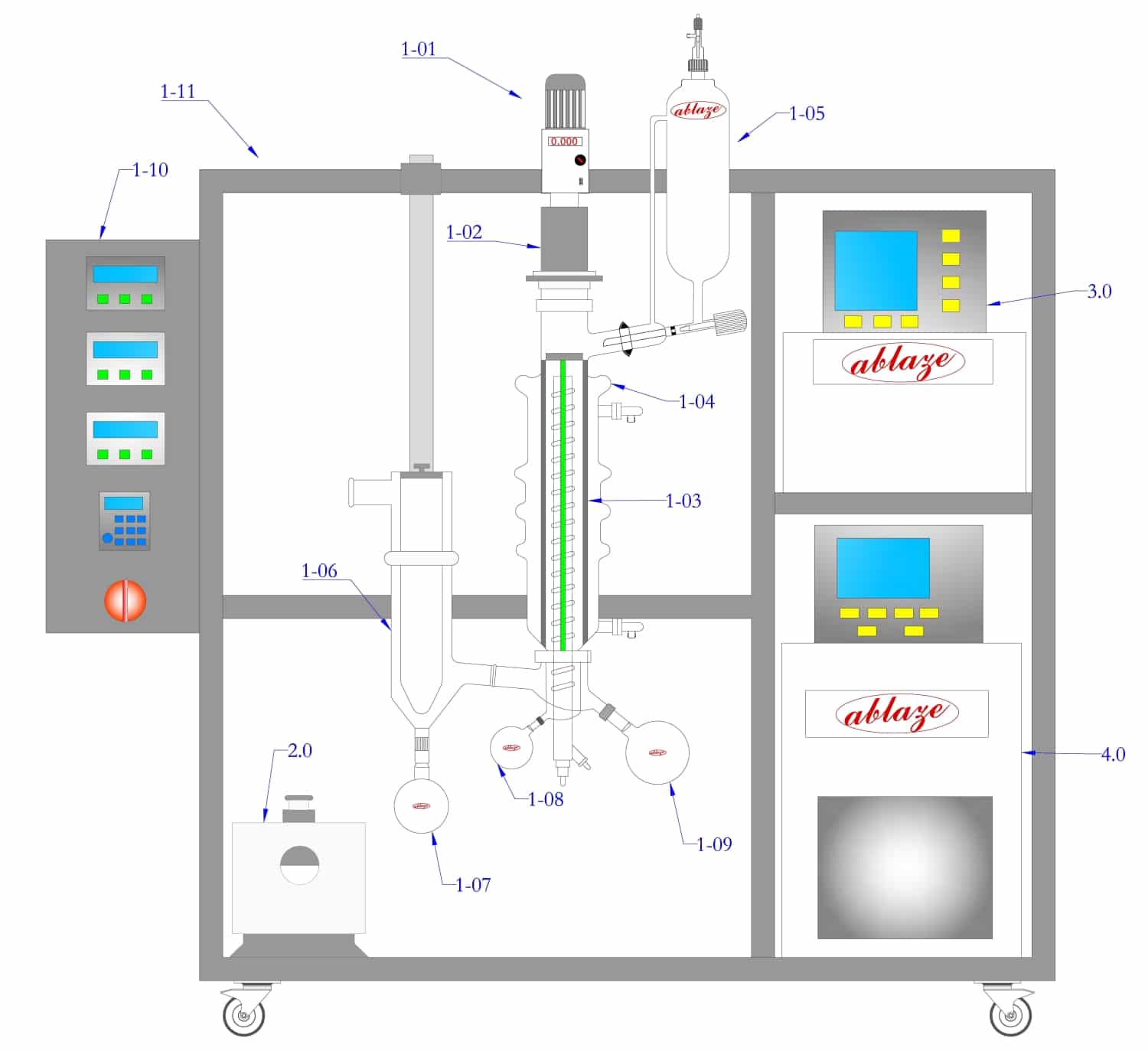

The Single Stage Distillation Plant runs at 2 to 5 liters per hour, with shorter run times possible. This is a complete system including the feed vessel, Short Path Evaporator and internal condenser, hot oil heater, condenser cooling system, cold trap, and vacuum system. The Short Path Evaporator and internal condenser and product piping is Short Path distillation equipment: A simple boiling flask with Vigreux condenser can be used to produce distillate. This is the most economical option but, also has the lowest yeilds. A good example of can be found on Google or here. The next step up in production efficiency is the Kugelrorh thin film distillation apparatus. 03.07.2012 · This chapter covers different types of chemical process diagrams, how these diagrams represent different scales of process views, one consistent method for drawing process flow diagrams, the information to be included in a process flow diagram, and the purpose of operator training simulators and recent advances in 3-D representation of different chemical processes.

Short path distillation diagram. Choose correct short description(s) of a real object for which this would be the correct free-body diagram a. A baseball player sliding into second base. b. A plane slowing down in the air. c. A... A general schematic diagram for LA separation by membranes is shown in Fig. 3. Fig. 3. ... “The effect of evaporator temperature on lactic acid purity and recovery by short path evaporation, ” Separation Science and Technology 50(10), 1548-1553. DOI: /10.1080/01496395.2014.975363. Komesu, A., Wolf Maciel, M. R., Oliveira, J., Martins, L. H. S., and Maciel Filho, R. (2016). “Purification ... 4.2.6 Short Path Distillation. Short-path distillation is usually treated as an . ... (Figure 9: Diagram of a T ypical Industrial Distillation. T ower.) 5. Applications. 5.1 Scientific Uses. 16 Dec 2016 — Step-by-step on how to operate the fractional distillation hardware properly · turn heat and stir off. · allow vacuum to dissipate energy in ...

Short-path distillation is a distillation technique that involves the distillate traveling a short distance, often only a few centimeters, and is normally ... 8 Jun 2020 — Short path distillation utilizes an apparatus with a multi-position receiver and condensing head. This process is very limited in scale and ... 23 Oct 2018 — Short-path distillation is a simple technique that involves the distillate traveling a short distance. This technique is used in many types of ... You only have to indicate the short deadline and our support team will help pick the best and most qualified writer in your field. The writer will confirm whether they will submit the paper within the set deadline. After confirmation, your paper will be delivered on time. Do you reuse the papers you write for clients . We never at any time reuse the papers we write for our clients. We also do ...

Distillation. Short path distillation is currently the most common technique. With short path distillation, the oil is exposed to heat and deep vacuum, which are used to separate various cannabinoids and terpenes from concentrate. In the diagram below, heat is introduced in step 1 via the mantle to evaporate the cannabinoids and terpenes. Short Path Fractional Distillation. The winterization process consists of 200 proof alcohol being added to the raw extract. It’s mixed well, then put in a deep freeze overnight. Then, it’s filtered through a funnel and flask, to remove the plant waxes. Usually a vacuum pump is used as well. contactor in a distillation tower and shows the primary functions desired: - Mixing rising vapor with a falling fluid. - Allow for separation after mixing. - Provide path for liquid to proceed down the tower. - Provide path for liquid to proceed up the tower. Figure 6 depicts a perforated tray contactor with certain accoutrements required to ... The short-cut methods available can be divided into two classes: 1. ... Thiele diagram, or the other methods developed for binary systems. ... Hengstebeck considers that in a typical distillation the flow-rates of each of the light non-key components approaches a constant, limiting, rate in the rectifying ...

These ranged from short-term problems such as scheduling and inventory control to long-term problems such as strategic planning and resource allocation. George Dantzig, who in 1947 developed the simplex algorithm for Linear Programming (LP), provided the single most important impetus for this growth. To this day, LP remains one of the most widely used of all O.R. techniques and despite the ...

Bench scale short path vacuum distillation set up with 3-position cow receiver. Bench scale fractional distillation apparatus with reflux and Vigreux column.12 pages

Types of Distillation Processes Most Applicable to the Farm There are two general types of distillation processes that appear applicable to farm-size fuel alcohol production with present technology. One is the continuous-feed distillation column system, in which a beer containing a constant alcohol content is continuously pumped into a column.

This type of cannabis distillation is very straightforward at a basic level. The name refers to the distance that distilled vapor travels in the equipment. It ...

Short path distillation is a distillation technique that involves the distillate travelling a short distance, often only a few centimeters, and is normally done at reduced pressure. [1] : 150 A classic example would be a distillation involving the distillate travelling from one glass bulb to another, without the need for a condenser separating the two chambers.

Steam distillation experiment calculations

Equations 5 and 7 and the definition of q we get: q 1 y= --x---Xp q-l q-1 (10) This is known as the equation of the feed line. The two operating lines and the feed line are plotted on the - y diagram as shown by Figure 2. The number of theoretical stages can be determined by using these lines and the equilibrium line.

01.01.2014 · Kenneth Hickman was one of the pioneers in the development of molecular and short-path distillation from 1910 to 1925. Starting with isotope separation, the first application was probably made by Brönsted and Hevesy (1920) to separate the isotopes of mercury. Early molecular stills for labile products were designed by H. I. Waterman, while the “truly molecular still” was first applied to ...

03.07.2012 · This chapter covers different types of chemical process diagrams, how these diagrams represent different scales of process views, one consistent method for drawing process flow diagrams, the information to be included in a process flow diagram, and the purpose of operator training simulators and recent advances in 3-D representation of different chemical processes.

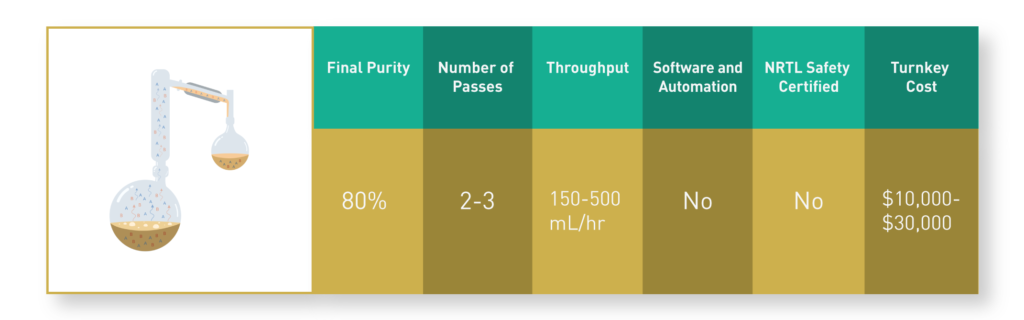

Short Path distillation equipment: A simple boiling flask with Vigreux condenser can be used to produce distillate. This is the most economical option but, also has the lowest yeilds. A good example of can be found on Google or here. The next step up in production efficiency is the Kugelrorh thin film distillation apparatus.

The Single Stage Distillation Plant runs at 2 to 5 liters per hour, with shorter run times possible. This is a complete system including the feed vessel, Short Path Evaporator and internal condenser, hot oil heater, condenser cooling system, cold trap, and vacuum system. The Short Path Evaporator and internal condenser and product piping is

0 Response to "44 short path distillation diagram"

Post a Comment