43 sand point well diagram

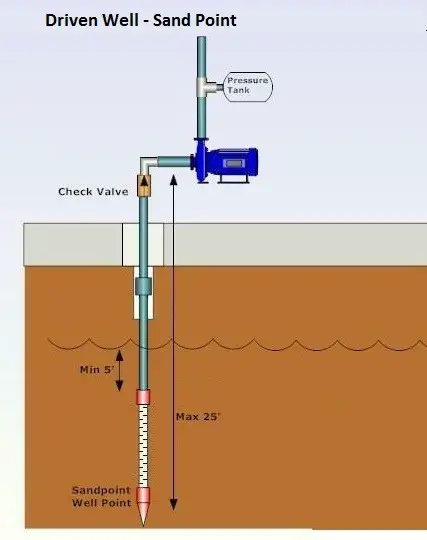

Complete sand point and pump kit. Besides individual sand points available now, we also offer a do-it-yourself sand point and pitcher pump kit with instructions for driving your own well. You will need to purchase 1 1/4″ galvanized pipe locally, which generally costs about $3 a foot. In areas with sufficiently sandy soil where the water table is within 25 feet, a standard sand point well with a simple hand pump has allowed for rural access to water all year. The pump kit works by driving a specially-designed well point into the ground and, eventually, into shallow water tables.

Sand point wells drive through the soil to the water table and use pumps to get water to the surface. These wells are useful for emergency water or for livestock and crops. Installation of a sand point well is simple and an accessible weekend project for the average property owner.

Sand point well diagram

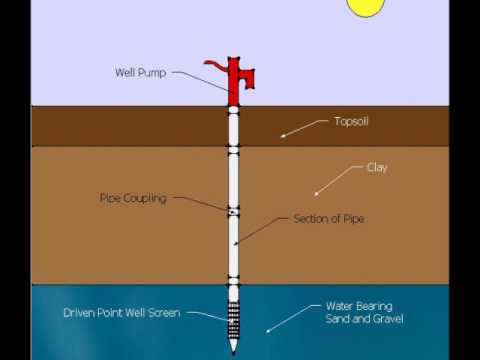

It's also good to be aware of the ground for which the well point has to travel through. Coarse sand for example, is the easiest to drive a point through where fine sand is extremely hard since the fine sand would grip the point. Sharp gravel is nearly impossible to drive a well point through since it will tear the screens. Drive pipe coupling. Water. Table. Screen. Well point. Drive pipe. Post driver. Driven Point. (Sand-Point) Wells. PUB-DG-022 2020 ...12 pages A sand point well offers many potential benefits over a drilled well. For example, sand point wells are typically less expensive and can generally be installed pretty much anywhere on the property. Since the equipment used to install a sand point well is smaller, the process is also far less invasive than drilling a well.

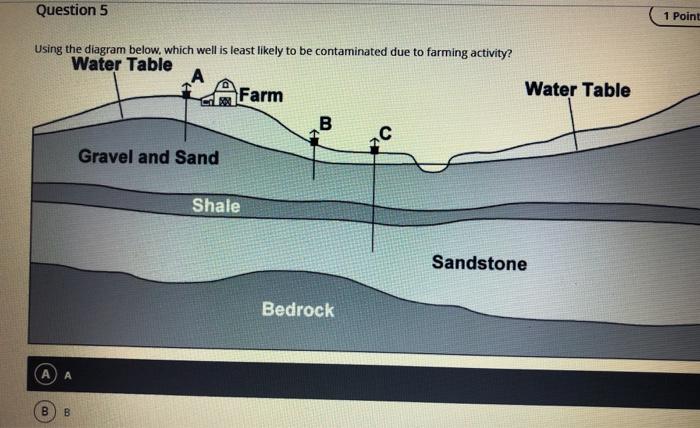

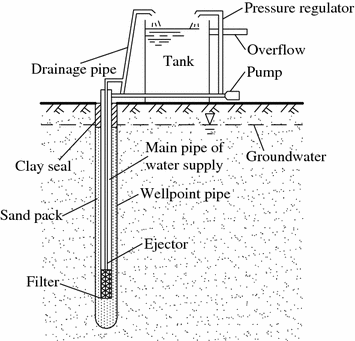

Sand point well diagram. Sand or well points are limited to areas where water bearing sand or gravel lies below the surface, and where there are no boulders or rocks to interfere with the driving into the ground of the point. The amount of water any "one" well point will supply is usually rather limited. ... (SEE DIAGRAM ON PAGE 8) STEP 9 TANKS INSTALLATION 5. That relatively greater air pressure all around you is what then pushes the soda up the straw. That is essentially how a shallow well jet pump works. Many people choose to drive their own well point, and this is the type of pump system most commonly used. Water has weight. If you dive for pennies in the shallow end of a swimming pool, you don't ... Download scientific diagram | Diagrams of a sand-point well and a cased well such as those typically used in the study area. from publication: Is Septic ... A Sandpoint Well is a shallow water well source obtained from no more then 25' below the ground. In areas where the ground under the soil is quite sandy and there exists a high water table Sandpoint Wells have in the past, and still can be found in use today, for potable and non-potable uses.

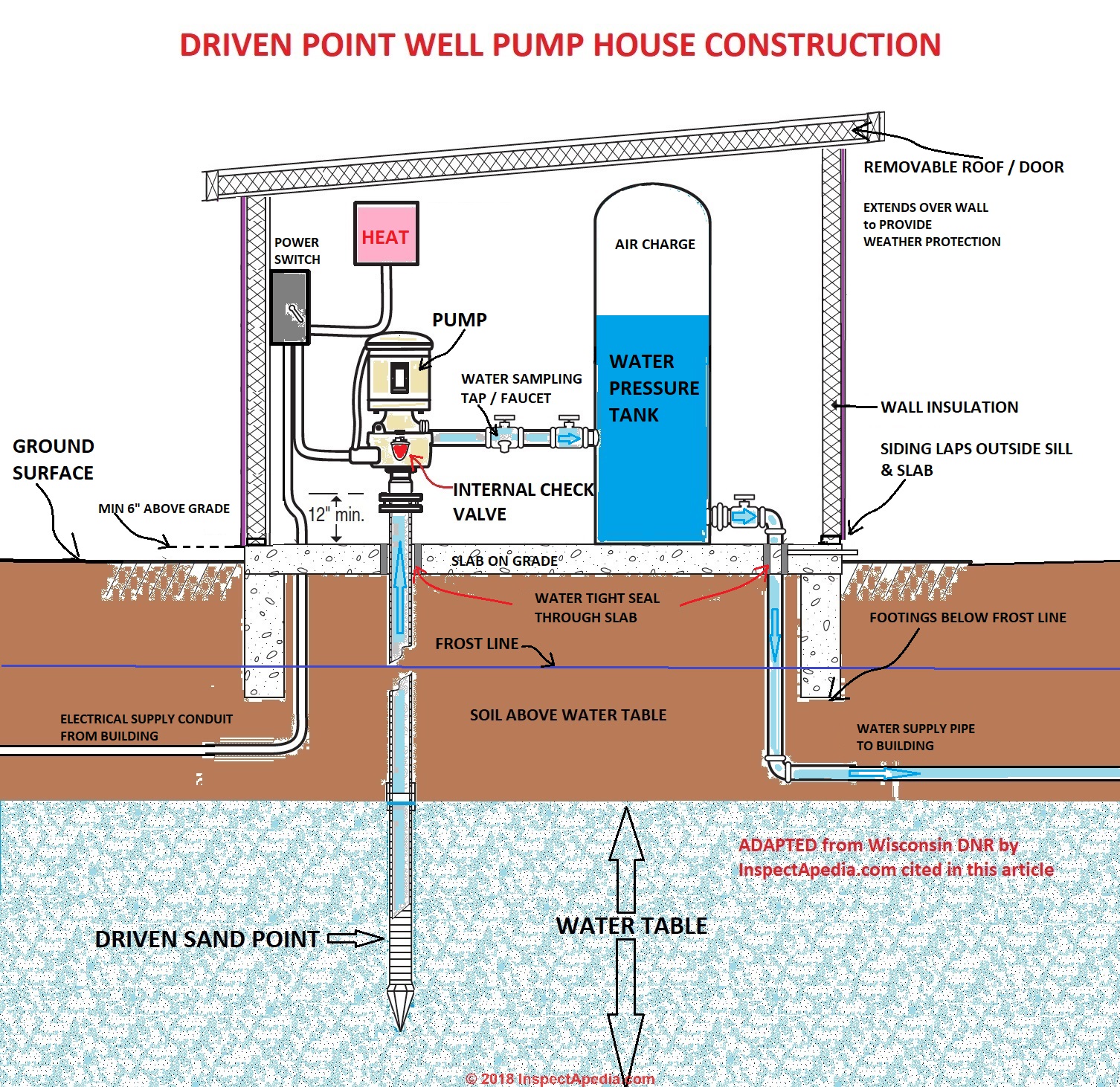

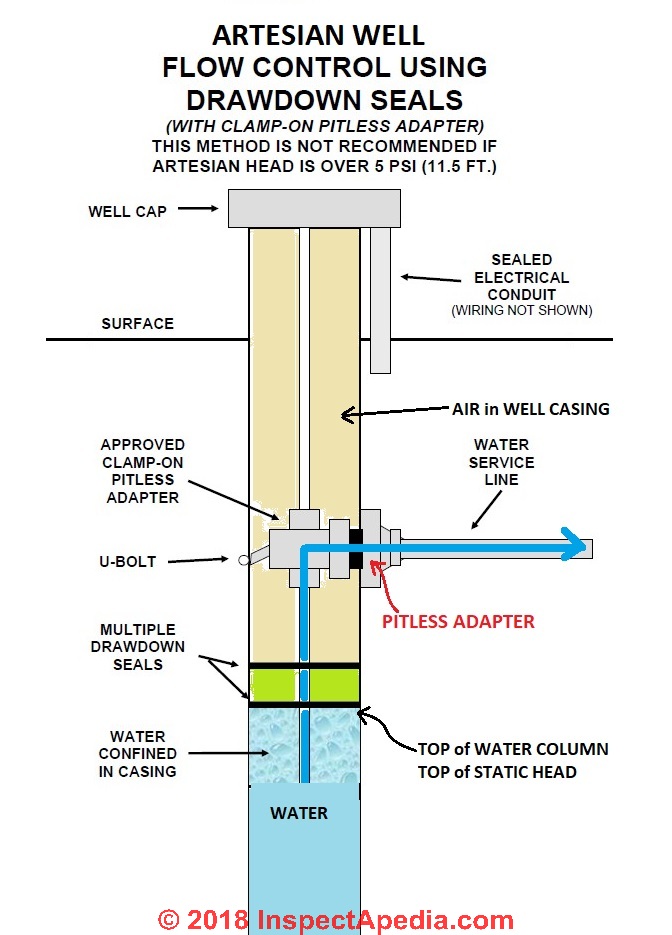

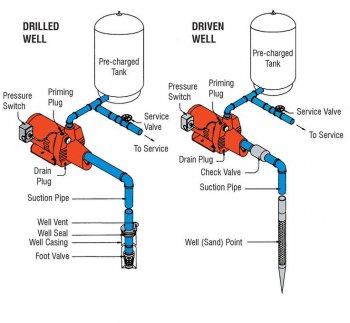

• Well seal or pitless adaptor • 1" discharge piping HOTLINE 888.956.0000 www.RedLionProducts.com Precharged Tank Service Valve To Service Pressure Switch Priming Plug Drain Plug Suction Pipe Well Vent Well Seal Well Casing Foot Valve DRILLED WELL DRIVEN WELL Well (Sand) Point Drain Plug Suction Pipe Check Valve Precharged Tank Service ... Acquire the items necessary to drill a driven point well from your local hardware store, including a 3 to 5-foot-long sand point, four sections of 5-foot-long pipe with a 2-inch diameter, special ... This stainless steel well point drives into all types of soil. Engineered to provide an ideal combination of easy driving, effective sand control, corrosion resistance and strength. 3-step bonding design prevents the screen from peeling back. Other names are instantaneous well or sand-point well. There are different driving techniques : - Percussion driving - Water injection driving

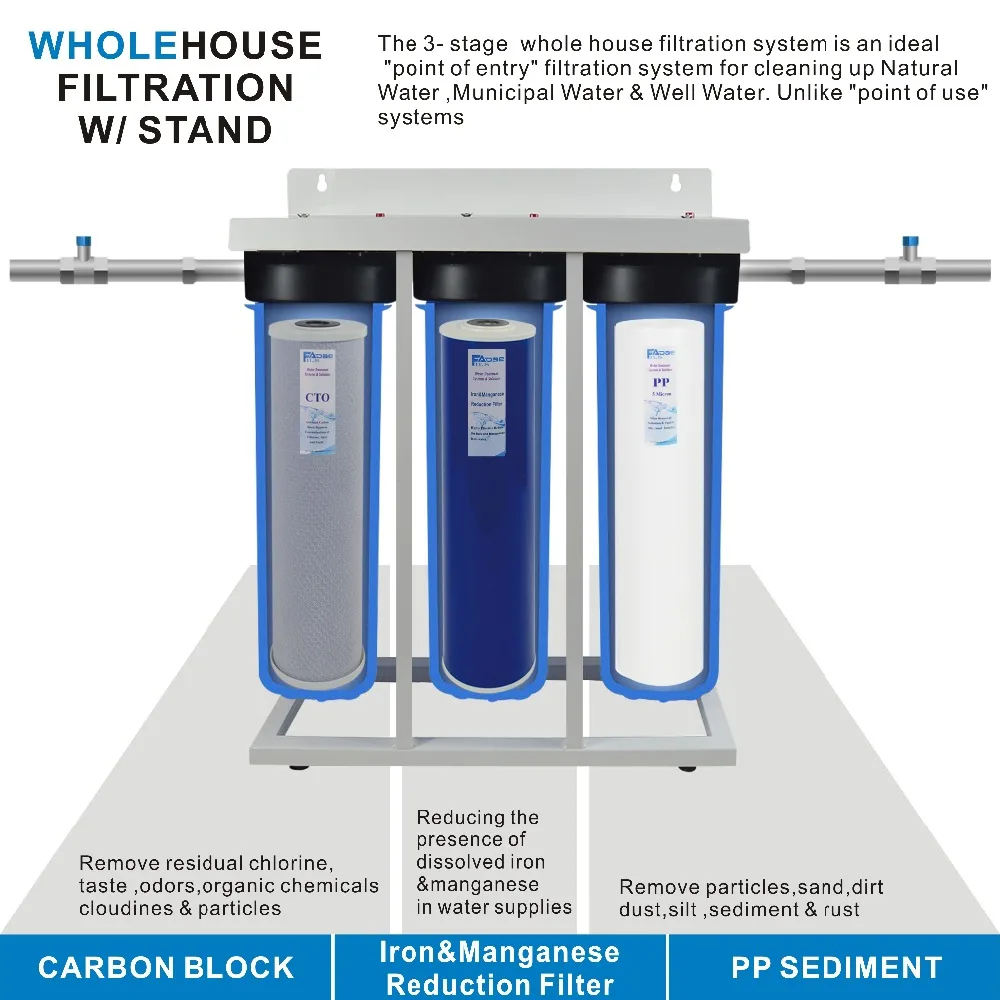

On 2021-03-08 by (mod) - OK to use "sand point" in drilled shallow well? @Allen R., If your well were a normal driven-point sand well then your piping arrangement is fine, and is often used. You would still have to deal with sediment problems. Maybe add a filter. Well pounding process from start to finish at our off grid cabin in Minnesota. With Larry Witt of Jack of All Trades Construction and Stump Removal 1-218-820... Push the casing down with reamer, adding joints of pipe as you go. 6. If needed, install pitless adapter below the frost line. 7. Pull drill pipe out of the hole, sacrificing the reamer. 8. Check well depth and surge the water through the perforations to clean the casing, or use garden hose to flush sand out. 9. mixtures the use of well points are aided by upper (0.60m - 0.90m long) compacted clay seals and sand-filtered boreholes (20cm - 60cm diameter). Upper clay seals help to maintain higher suction (vacuum) pressures and sand filters increase the amount of discharge. Filtered

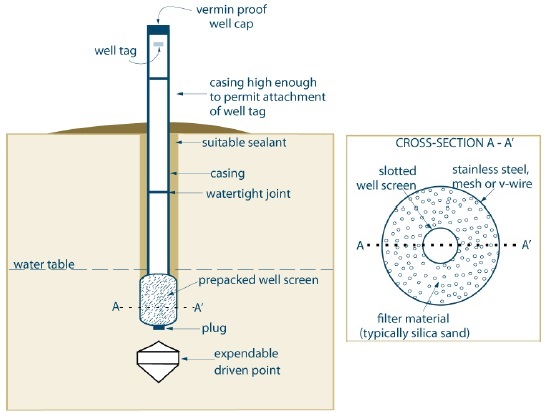

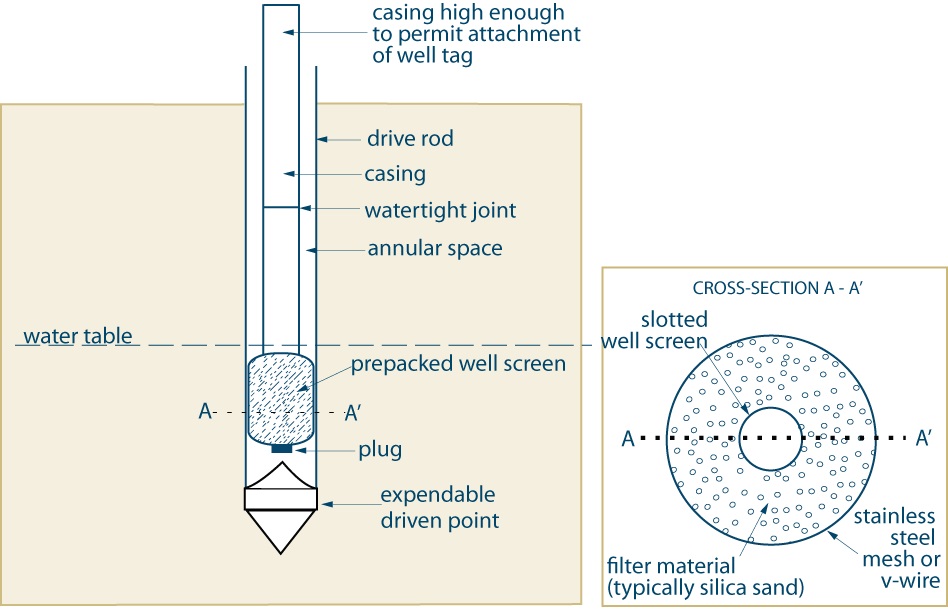

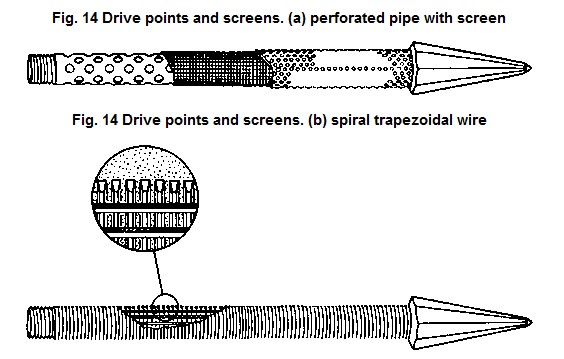

A driven point well - sometimes called a sand point - is a small diameter well made by connecting lengths of 1-1/4" or 2" diameter steel pipe together with threaded couplings. Threaded to the bottom of the string of pipe is a drive-point well screen. The screen is usually 2 to 3 feet long with a hardened steel tip or drive-point

Sand point wells. If the well casing can be pulled, the hole should fill naturally with native material, and no further work is required. However, if the casing cannot be pulled, a certified professional water well contractor's services will be required to grout the well properly. ... Diagram of an effective well-plugging method for large ...

The durability and efficiency* of a well depend to a large degree on its design, construction procedures and selection of casing and well screen. However, casings and screens alone comprise the principal substance of a completed water well. *An explanation of well efficiency appears in Appendix 1. Construction of Los Angeles Aqueduct, 1907-1913.

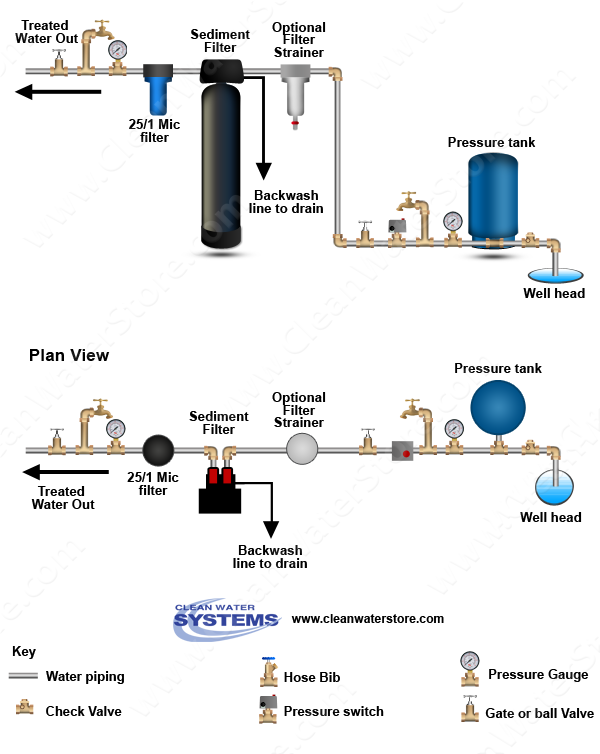

Diagrams --Typical Pump Installations. The information provided here is for educational purposes only. Technically qualified personnel should install pumps and motors. We recommend that a licensed contractor install all new systems and replace existing pumps and motors. Failure to install in compliance with local and national codes and ...

WELL COMPONENTS. Below are descriptions of the basic components found in a private water well. (Source: National Ground Water Association) Well Casing is the tube-shaped structure placed in the well to maintain the well opening from the target ground water to the surface. Along with grout, the casing keeps dirt and excess water out of the well.

A drive-point well — also known as a sand-point or well-point — is constructed using a pointed screen on the end of a series of tightly coupled lengths of steel pipe. The well casing pipe, which is usually 1¼ inches in diameter, is driven into the ground with a heavy hammer or well driver until the point is below the water table.

Continuous-flight, spiral auger well drilling rigs are found in those parts of western, central and northern Lower Michigan where sand is the predominant glacial drift material. In some areas, augers are used to drill the upper portion of the well and then the well is completed with the cable tool method.

A driven-point well - sometimes called a "sand point" - is a small diameter well made by connecting lengths of 1-1/4" or 2" diameter steel pipe together with threaded couplings. Threaded to the bottom of the string of pipe is a drive-point well screen. The screen is usually 2 to 3 feet long with a hardened steel tip or "drive ...

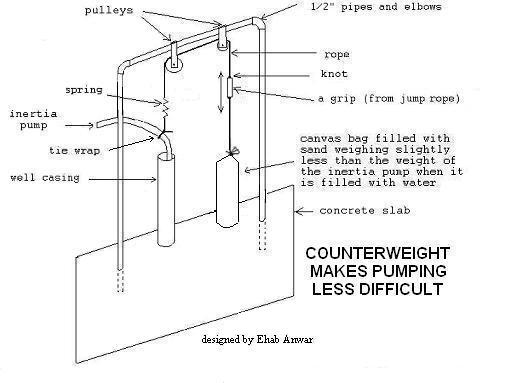

the perforated point. This draws fine sand and dirt into the well. 4 When a large driver is used, a tripod is required with a lift and pulley as illustrated. Can be assembled from 2x4s and pulleys. Drive the well point and pipe into the earth. Remove the drive cap and add pipe* as required using drive couplings. Rotate clockwise timeto using a

I am attempting to drive a sand point well at a property in northern Wisconsin that i recently purchased. I purchased a 2" sand pint and 2" galvanized pipe. I have driven this down just over 20'. When i check for the water depth with a string and weight, i hit water at 15'. So i have 5' of water.

TYPICAL SHALLOW WELL JET PUMP INSTALLATION 1. Shallow well jet systems can be used when the depth of the water is no more than 20'. Water depths of more than 20' but less than 80' deep would use a deep well jet system or submersible pump. A submersible pump can also be used in shallow wells. 2. We recommend a captive air pump tank.

There's either a suction leak or the well isn't supplying water. NOTE: There can be water in the well but it may not be producing water! As ValveMan said "Sounds like your well is just not making any water. Try pouring water down the sand point. If water doesn't go down freely, it won't come up freely".

Diagram: example of a dug well . Sandpoint Wells: Sand-point or driven- point wells consist of a small-diameter casing ranging in size from 2.5-5 cm (1-2 in.). Sand-point wells are constructed in sand and gravel aquifers and are either driven or jetted (inserted using high-pressure water) into the ground. Sand-point wells are usually only

A screened “well point” located at the end of the pipe helps drive the pipe through the sand and gravel. The screen allows water to enter the well and ...1 page

The well point was set at that depth, but the water table was several feet higher. It was just necessary to drive the point to that depth to access the permeable sand and gravel layer. The natural water table filled the well pipe to an equilibrium level that was higher than the total depth of the sand point.

A sand point well offers many potential benefits over a drilled well. For example, sand point wells are typically less expensive and can generally be installed pretty much anywhere on the property. Since the equipment used to install a sand point well is smaller, the process is also far less invasive than drilling a well.

Drive pipe coupling. Water. Table. Screen. Well point. Drive pipe. Post driver. Driven Point. (Sand-Point) Wells. PUB-DG-022 2020 ...12 pages

It's also good to be aware of the ground for which the well point has to travel through. Coarse sand for example, is the easiest to drive a point through where fine sand is extremely hard since the fine sand would grip the point. Sharp gravel is nearly impossible to drive a well point through since it will tear the screens.

0 Response to "43 sand point well diagram"

Post a Comment