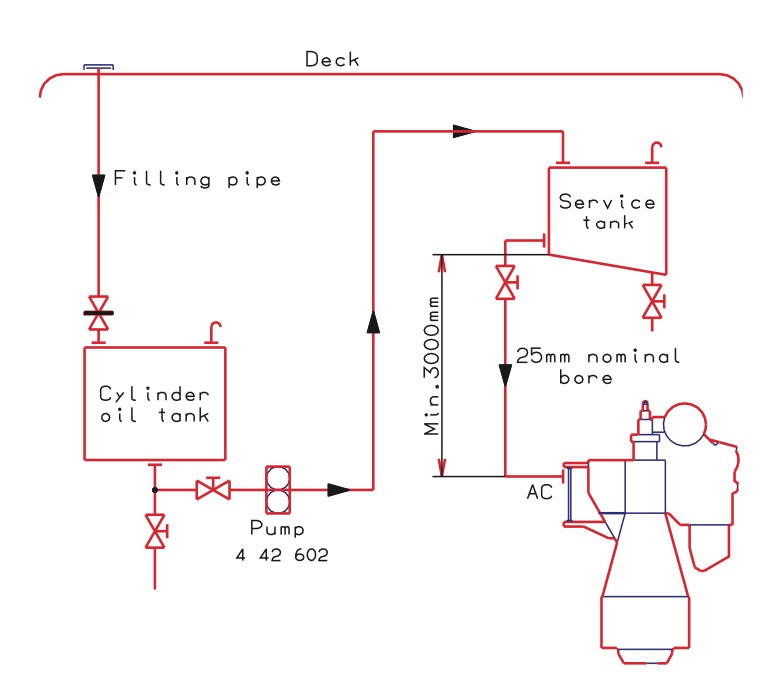

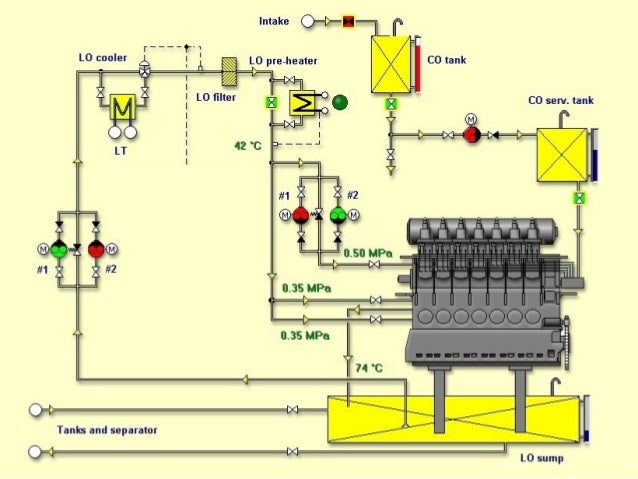

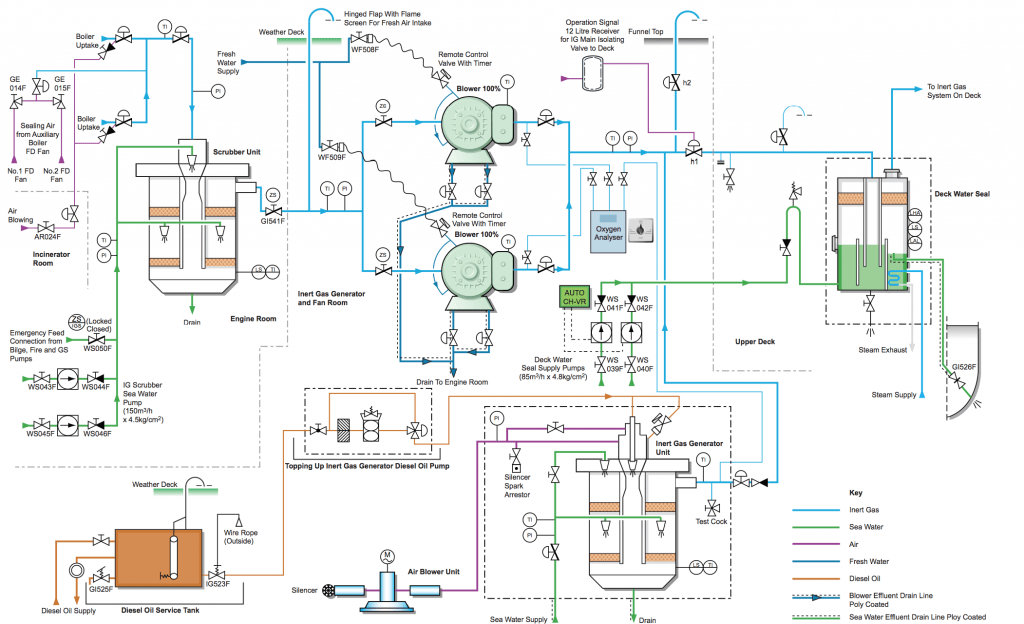

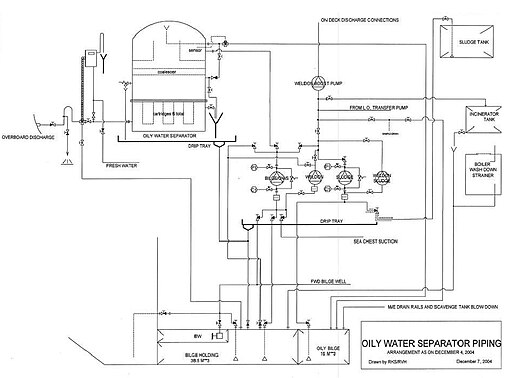

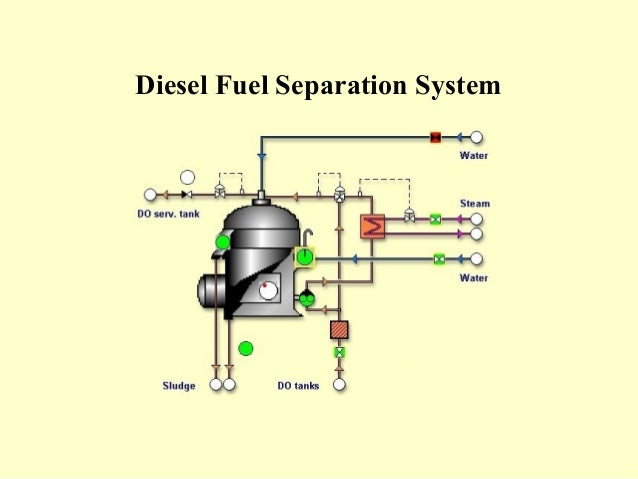

40 fuel oil piping diagram

OPW FlexWorks Fuel Oil Piping Systems are designed to provide a reliable, secondarily contained, underground fuel supply system to generators and boilers from remote fuel tanks. Typical applications include a 3/4" or 1" supply and a 1" overflow return line running from a remote AST or UST to a generator engine or boiler Day Tank. This technical manual contains copyrighted material DEPARTMENTS OF THE ARMY AND THE AIR FORCE WASHINGTON 26, DC., 5 September 1966 TM 55-4018-1/TO 88G1-6-21 is published for the use of all concerned.

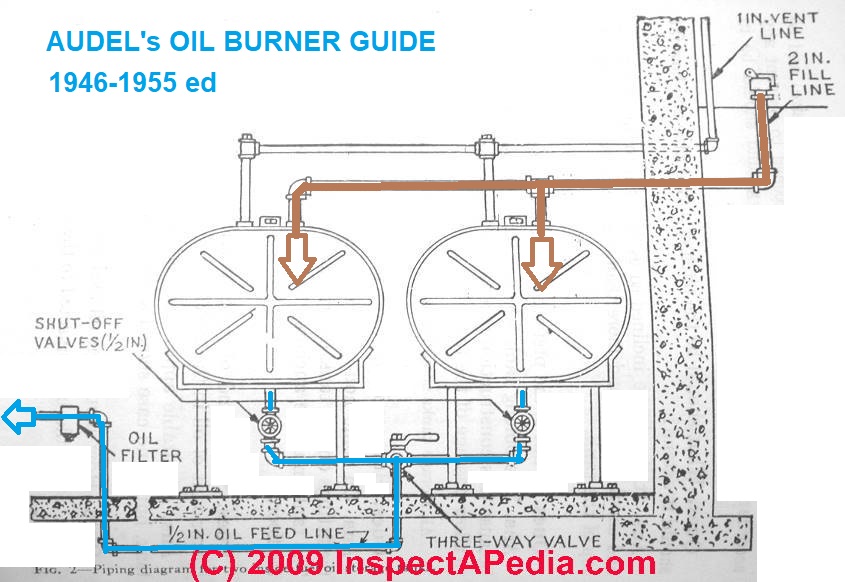

8.4 Fuel Return Piping. A return line from a burner or pump to a supply tank shall have no valves or obstructions and shall enter the top of the same tank. 8.5 Supply Piping to Oil-Burning Appliances. 8.5.1 All piping shall be connected into the top of the supply tank. Where two tanks are cross-

Fuel oil piping diagram

Installations should avoid putting fuel oil where it is exposed to temperature extremes. The pour point limit for #1 and #2 fuel oils not seasonally-adjusted is 0 o F and 20 F, respectively LENGTH OF RUN (L) The length of piping from tank to fuel unit is calculated using the following burner oil piping can be found in Table 6 this page, Figure 11 on page 12, and Figure 12 on page 13. It is very important to properly size the oil suction line and oil filter, to provide fuel flow to the burner without exceeding 10" suction pressure (vacuum) at the oil pump suction port. The method to properly size copper tubing is outlined To speak to a Preferred engineer who knows NFPA fuel codes and is experienced with fuel oil storage and handling systems, call (203) 743-6741. INSTRUCTIONS The goal is to select a pump that meets the flow and pressure requirements of your project, and design the piping system so that the suction on the pump inlet, and discharge pressure at the ...

Fuel oil piping diagram. fuel oil to diesel is to in pipe specifica71t* oss-e4a a. 2'. n-rj 1/2* n-rj e. cp with a to tx xØØØl set nessi.Æ psig ax ftÆl ort so 1/2- to fl.-el on- ecircu-at1œa 2 oil rev. per oe-6345 ed. c. 11 0.6 retired exe>ptic date cate cate civil elec. oconee a istec rture condition 1 power nuclear station units 1, 2 & 3 flow diagram of fuel ... No.2 Burner Fuel Oil Systems, Burner Fuel Oil Systems - Standard Piping Diagram Author: Department of Veterans Affairs, Office of Construction and Facilities Management, Facilities Standards Service Subject: standard detail Created Date: 8/5/2021 6:34:18 PM Learning objectives. Know the nine key considerations for designing a generator set fuel oil system. Consult authorities having jurisdiction to review the proposed design early in the project. Recall important rules-of-thumb when designing a fuel oil system. Backup generator sets (gensets) are critical to business continuity and life safety. GAS & #2 FUEL OIL SUPPLY DESIGN GUIDE . Multi-Fuel, Condensing Boilers • Latest Update: 2/28/2018 . TECHNICAL APPLICATION GUIDE This document provides Fuel Components, Pressure, Piping, and Venting for MFC Series boilers. Applies to MFC Series Models: • MFC 3000 • MFC 4000 • MFC 5000 • MFC 6000 • MFC 8000 MFC 10000 Gas Train

Fuel oil piping shall be tested in ac-cordance with NFPA 31. SECTION 1309 OIL TANKS FOR ONE- AND TWO-FAMILY DWELLINGS AND TOWNHOUSES 1309.1 Materials. Supply tanks shall be listed and labeled and shallconformtoUL142forabove-groundtanks,UL58forun-derground tanks and UL 80 for inside tanks. B. Handle fuel oil system components carefully to avoid damage to material component, enclosure and finish. C. Store fuel oil system components in a clean, dry space and protect from the weather. PART 2 - PRODUCTS 2.1 PIPE AND FITTINGS: A. Fuel Oil Piping Buried Below Ground: 1. Fuel oil system piping diagram. b. Operation. The fuel oil is pumped into the tug. propulsion engine, the diesel auxiliary sets, and the. heating system oil burner by gravity flow. The galley. at the starboard side deck hose connection, and using. range day tank is filled by using the rotary hand pump, main fuel tank. The Day Tank must not be more than 18' higher than the lowest fuel level in the main fuel tank. Never locate the Day Tank in a confined space without consideration for accidental fuel spillage and use a rupture basin when necessary. Never locate the Day Tank near a surface or object which may be adversely affected by fuel oil. Never

fuel oil storage tank in a separate room located at a building level above the diesel room. There is no elevated fuel oil piping adjacent to the engine. The fuel oil piping between the day tank and the engine drops down from the tank and runs below the elevation of the engine until it reaches the engine. The transfer pumps and auxiliary that is found in the building. Storage tanks and buried piping will not be addressed. Description of a modern diesel fuel system as a standby energy source. The modern diesel fuel or fuel oil systems are used differently than systems designed a decade or more ago. In early fuel oil system designs, boilers were the primary user of the fuel. The ... AST FACILITY PIPING Piping is used to transfer fuel from the delivery source, such as barges or trucks to the ASTs at the facility (transfer or fill piping), between tanks and dispensing pump (manifold piping), and from facility tanks to other associ-ated tanks and other sources (distribution piping). Following is some basic FUEL OIL PIPING AND STORAGE SECTION 1301 GENERAL 1301.1 Scope. This chapter shall govern the design, installa-tion, construction and repair of fuel-oil storage and piping sys-tems. 1301.2Storageandpipingsystems.Fuel-oil storage systems shallcomply withSection603.3 of theFireCode.Fuel-oilpip-ing systems shall comply with the requirements of this ...

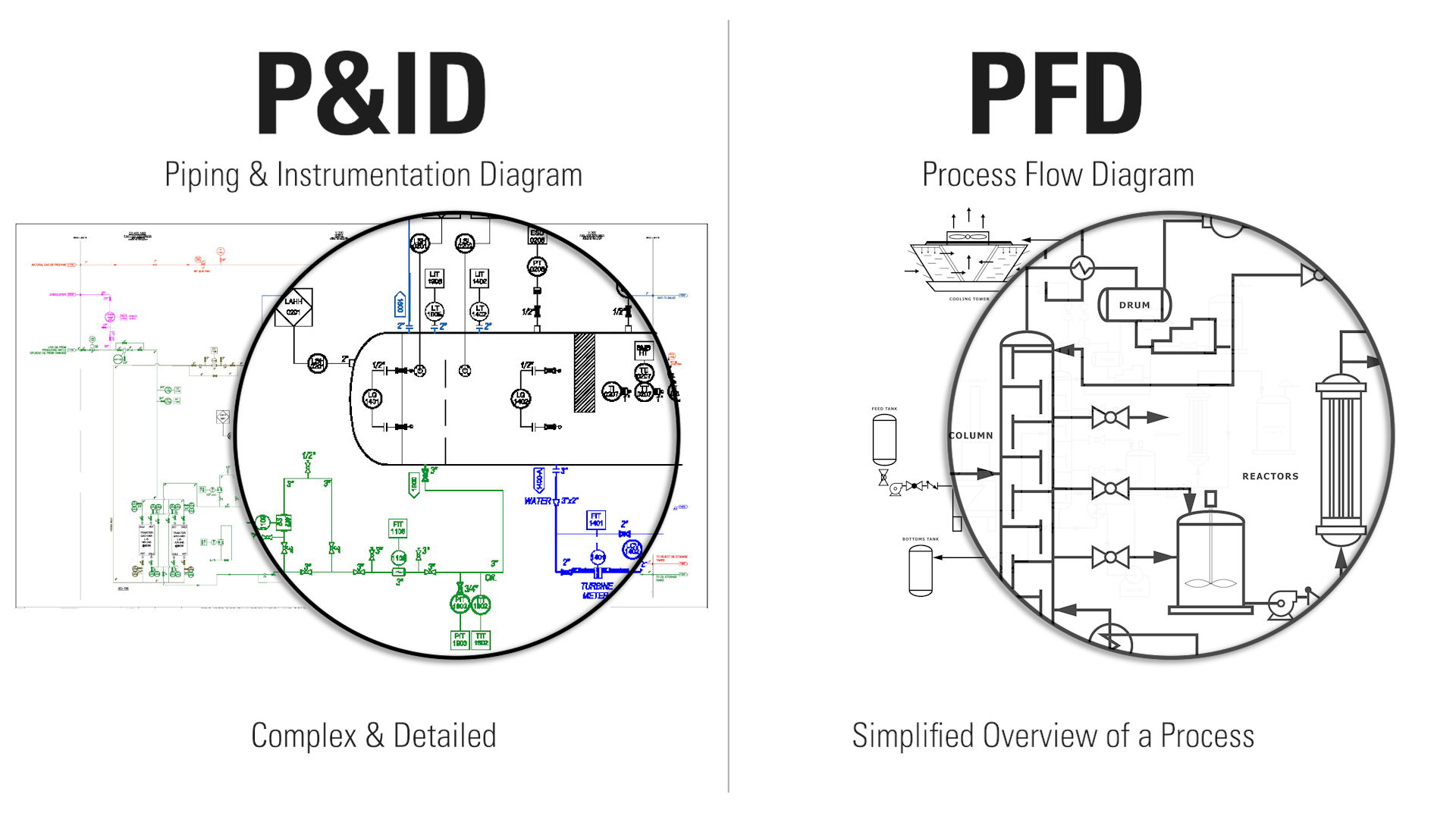

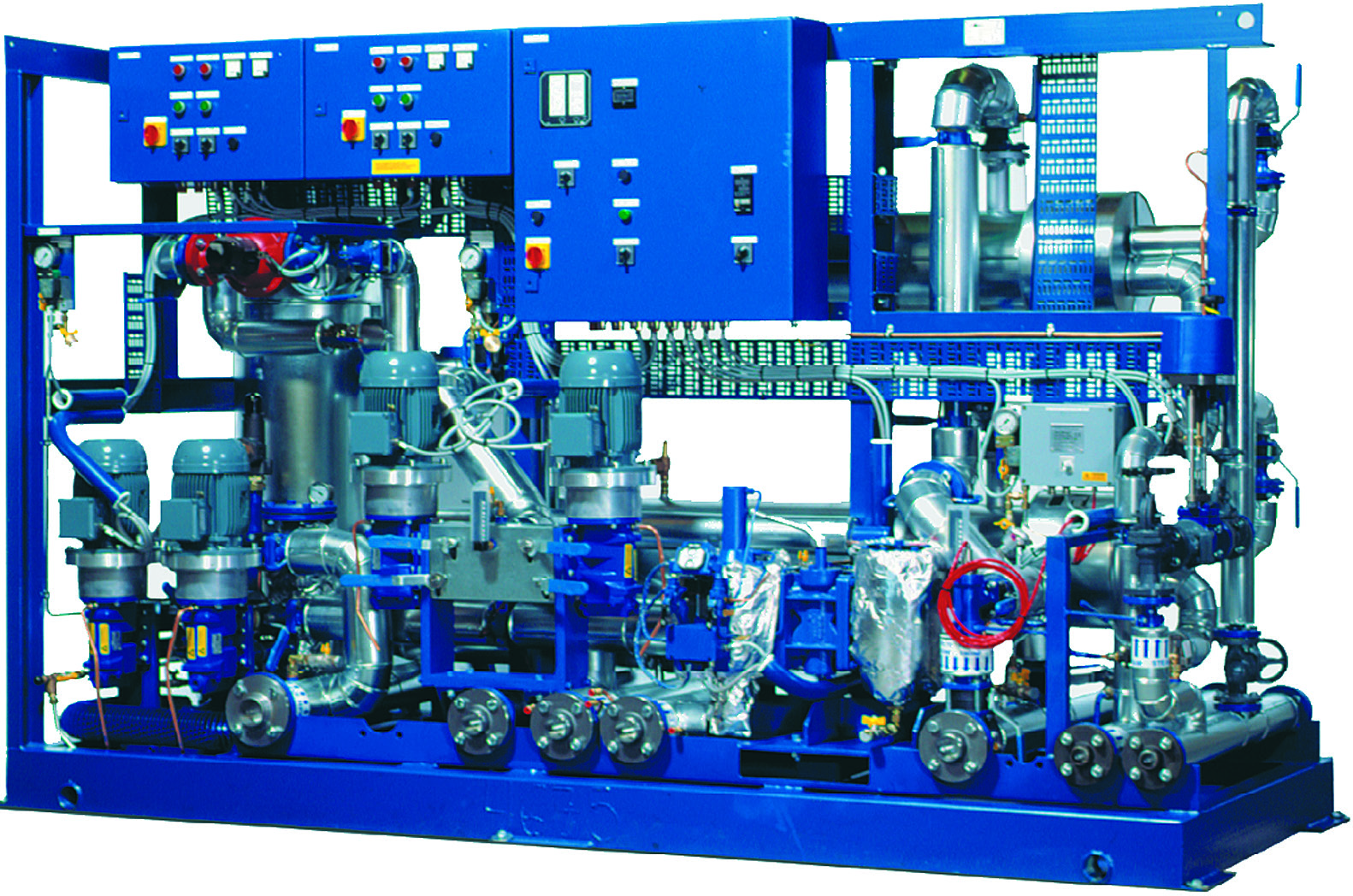

Fuel Oil Piping Diagram. An engineering guide to modern fuel systems this publication is intended as a resource for designers installers and system operators. Part 2 products 21 pipe and fittings. Flexible Piping Systems For Fuel Oil And Generator Applications.

4.3.2.4 Vent Piping for Aboveground Tanks. Piping for normal and emergency relief . valve venting shall be constructed in accordance with chapter 5 of NFPA 30. 4.3.2.5 Tank Openings Other than Vents for Aboveground Tanks . 4.3.2.5.1 Each connection to an aboveground tank through which liquid can normally

Fuel Oil Piping Diagram for Main Tank, Day Tank, and Diesel Genset. Fuel Oil Piping Diagram for Main Tank, Day Tank, and Diesel Genset. Fuel oil systems design has always been a challenge for most designers. It involves thorough knowledge of NFPA codes, EPA regulation, local and state laws, and client requirements.

examination for the certificate of Fitness for Supervision of Fuel Oil Piping And Storage System (P98). The study material includes information taken, for the most part, from relevant sections of the Building Code of New York. Other information describes the proper operation and maintenance of Fuel oil piping and storage systems.

Open And Sealed System Where The Oil Boiler And A Solid Fuel Stove Two Central Heating Zones And A Domestic Hot Water Dhw Cylinder Nrg Awareness

Where flexible copper is used, of course, is not for the fill and vent pipe to the oil storage tank but for piping fuel between the oil storage tank and the oil burner . Adding a few details on oil piping in Connecticut using Norwalk's code as an example . 47-22 Connections and unions.

1301.4 Fuel Tanks, Piping and Valves. The tank, piping and valves for appliances burning oil shall be installed in accordance with the requirements of this chapter. Where an oil burner is served by a tank, any part of which is above the level of the burner inlet connection and where the fuel supply line is taken from the top of the tank, an ...

vent piping, fill piping, etc.), be equipped with means for controlling the filling operations. o NFPA 37 (6.6.2) requires that engine-mounted Class II fuel tanks be filled by closed piping systems. Generator subbase diesel tanks ("belly tanks") appear to fall under this requirement.

pressure of the ANSI/ASME B16.5 piping system flanges at 100 degrees F (38 degrees C), see Table 1. Test hydrant and direct aircraft fueling systems and installation fuel pipelines with fuel that will be used in the pipeline or, at a minimum, a fuel with the same minimum specification flashpoint as the fuel that will be used when the piping is in

application type diagram see installation manual for complete instructions. install in accordance with all local codes. typical piping for conventional single boiler installation lb-500, lb-750, lb-1000 • safety relief valve setting should not exceed pressure rating of any component in the system. • piping should conform to local codes.

Gas Oil This is a light distillate fuel which does not contain any residual fuel. Gas oil is approximately ASTM No. 1 diesel fuel. Marine Diesel This is a distillate fuel that boils at a higher temperature than gas oil. The fuel varies from ASTM No. 2 diesel fuel to ASTM No. 4 diesel fuel. The composition can vary within the following range: ASTM

Oil Tanks and Piping Chapter 3 Chapter 3—Oil Tanks and Piping 3-3 Introduction The comfort, cleanliness and efficiency of today's oilheat systems rely on clean, uncontaminated fuel reaching the oilburner. To achieve this: • Install tanks properly. • Maintain tanks by regularly inspecting them and fixing minor defects before

To speak to a Preferred engineer who knows NFPA fuel codes and is experienced with fuel oil storage and handling systems, call (203) 743-6741. INSTRUCTIONS The goal is to select a pump that meets the flow and pressure requirements of your project, and design the piping system so that the suction on the pump inlet, and discharge pressure at the ...

burner oil piping can be found in Table 6 this page, Figure 11 on page 12, and Figure 12 on page 13. It is very important to properly size the oil suction line and oil filter, to provide fuel flow to the burner without exceeding 10" suction pressure (vacuum) at the oil pump suction port. The method to properly size copper tubing is outlined

Installations should avoid putting fuel oil where it is exposed to temperature extremes. The pour point limit for #1 and #2 fuel oils not seasonally-adjusted is 0 o F and 20 F, respectively LENGTH OF RUN (L) The length of piping from tank to fuel unit is calculated using the following

0 Response to "40 fuel oil piping diagram"

Post a Comment