41 how to use lock washers diagram

Lock Washers. Lock washers are a very popular locking choice especially with smaller-sized fasteners. Essentially, there are two types: spring action and tooth. Spring action washers include split, conical (Belleville) and wave. These washers, placed under the nut or screw head, compress as the fastener is tightened and the spring-back tension deters loosening. A tooth lock washer—internal ... 12 steps1.Place the lock washer under the threaded fastener. When used correctly, a lock washer will hold the nut or other threaded fastener in place. To help it ...2.Make sure your washer is tight against the fastener and other surface. To operate correctly, your lock washer must press against both the threaded fastener ...3.Tighten your threaded fastener. For small, general purpose jobs, tighten your nut or threaded fastener by turning a wrench or ratchet clockwise. Do this ...

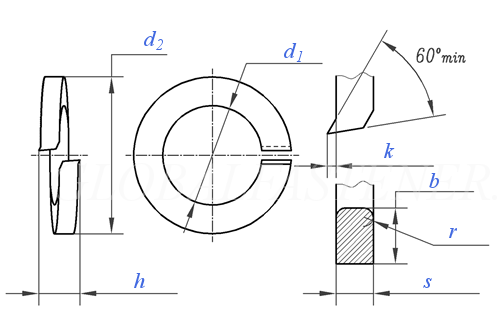

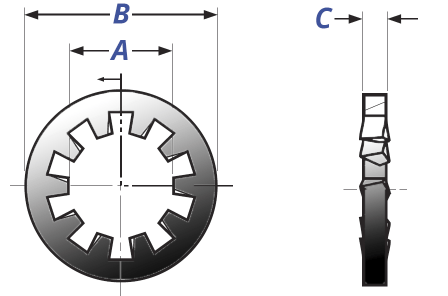

Helical spring lock washers are the most common form of lock washer and are best suited to applications with smaller loads. High-collar lock washers are a kind of split washer. Internal use lock washers have teeth made to bite into the nut/screw head and surface it contacts. They work best on small screws or screws used in electrical grounding.

How to use lock washers diagram

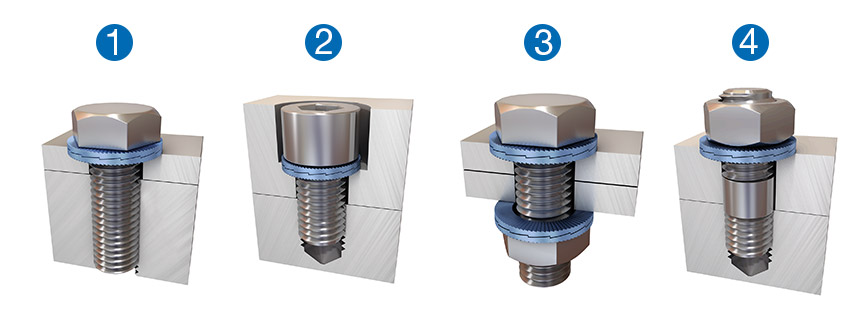

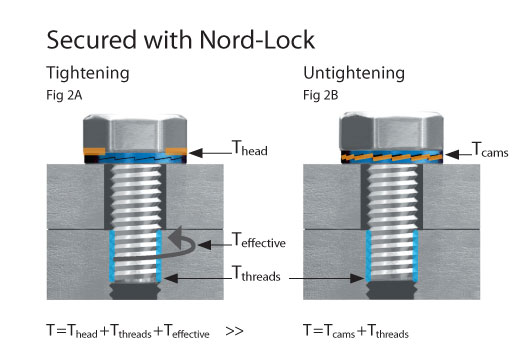

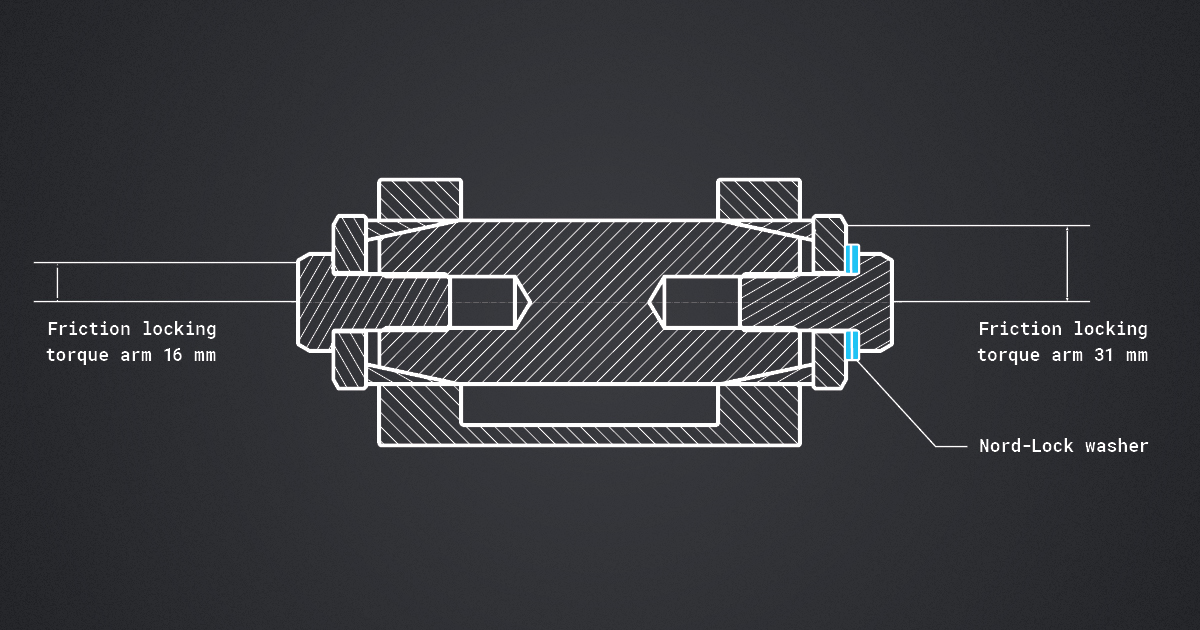

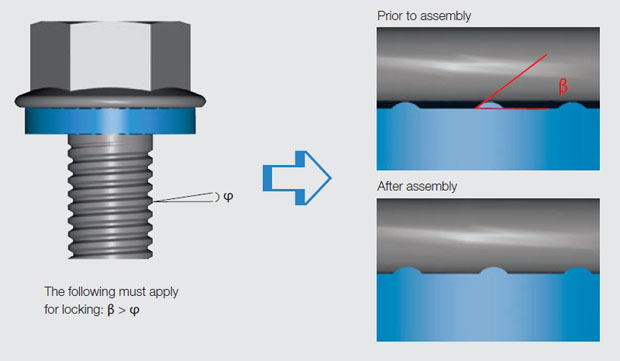

The flat washer can be used on the bolt side, nut side or both. If the assembly calls for o ther types of washers or hardware elements besides these two, they should go on before the lock washer. This way the tension created by the lock washer holds them all in place. It is very important that you do not tighten the lock washer too much. In this animated video, we explain the principle behind the Nord-Lock washers. Our original wedge-locking technology secures bolted joints, even when exposed... Step 1. Place the lock washer between the nut and the work surface if using a nut-and-bolt configuration, or between the fastener head and the work surface if using a tapped hole configuration. In other words, the bolt goes straight into the hole and doesn't poke out the other end, so no nut is used.

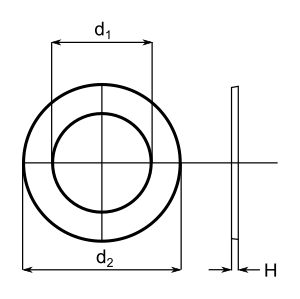

How to use lock washers diagram. Washers can follow ANSI, SAE, USS, and JIS sizes as well. We currently have a list of split lock, sealing, internal tooth, external tooth, flat, and flat retaining. Below I will go over what each one is and their use. Split Lock- Split locks are also called helical spring lock washers. These are made out of a spring coil that cut or split. Lock washers typically replicate the fasteners head, and offers little improvement over not using one. A hardened flat washer has a larger seating area against the retained component. Although elongation of a retainer reduces applied tensions, disruption of the seat has a similar effect. Instead of using an electronic speed sensor and throttle position sensor we will use a mechanical / hydraulic / electronic speed sensor and a vacuum / electronic throttle position sensor. ... Use a lock-up type torque converter if possible, ... Click here for 727 to 46RH swap wiring diagram $ 88.00. 1:12How to properly use a lock washer. Watch later. Share. Copy link. Info. Shopping. Tap to unmute. If playback ...20 Aug 2011 · Uploaded by aydinvideo

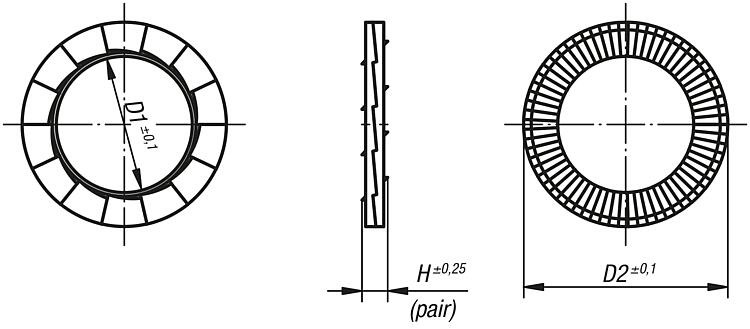

However general installation guidelines for lock washers will help you to choose what type of lock washer to use on your next project. Advertisement Step 1 Place an external tooth lock washer over the threads of a bolt or screw larger than 1/2-inch diameter. The head of the fastener should cover the teeth on the external lock washer. Video of the Day Step 2 Slide the neck of a small fastener ... 3:28Lock washers are used to prevent nuts, bolts, and screws from vibrating loose, and there are many kinds of ...31 Oct 2019 · Uploaded by Albany County Fasteners The outer diameter of regular Nord-Lock washers is designed for counterbore holes according to DIN 974, i.e. the washers fit under the head of standard bolts. Through-holes As for all locking washers, through-holes require two pairs of Nord-Lock washers - one pair for securing the bolt and a second pair for securing the nut. It uses either a copper penny or a washer snare lock. You have to use a pre-1985 copper penny, because the newer ones are junk and will break when bent. What you will need: A 1/16 in. diameter stainless steel cable; A 1/16 in. copper end stop; A 1/16 in. oval compression sleeve; A copper penny or 1/2 in. washer

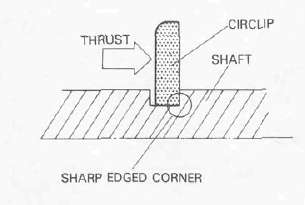

If it's too tight to fit the tips, twisting a small flat-blade screwdriver between the ends will spread them enough to fit the plier tips in. I rarely re-use the horseshoes, easier and more reliable to replace them with modern e-clips. To remove the e-clips, I do the same as Bob with a small slip-joint plier. A washer used to obtain a 'finished' look. Usually used with oval head screws. Split Lock The most common style of washer used to prevent nuts and bolts from backing out. External Tooth Lock A washer with external 'teeth'. Used to prevent nuts and bolts from backing out. Ogee Thick, large diameter, cast iron washers with a curved or Particularly suitable for dynamic loads - including when using lubricants; Can be re-used; Very easy to install and remove (wedge lock washers are supplied as a pre-assembled pair) Also suitable for high-tensile bolts of 8.8, 10.9 and 12.9 and their respective nuts If you're using a lock washer in any variety (including star type, split-ring type, or wavy type) to keep the nut or bolt from coming use, the washer is used on the side that's most likely to turn and drive into the surface - which in most case is the nut. The only time when you will use the washer on the bolt side is when the bolt screws ...

304 Stainless Steel Din 6798 J Internal Sawtooth Lock Washer Buy Din6798 304 Stainless Steel Internal Teeth Serrated Lock Washers Internal Toothed Lock Washer Stainless Steel Din 6798 J Saw Tooth Lock Washer Product

How to use lock washers diagram. This joint looks complicated but its only two cuts. Lock washers are usually used when bolting two pieces of metal together. 3x3custom tamar recommended for you. What would you call it. Washers are used to strengthen the connection by distributing the force that is being applied by the bolt over a broader area. Place the lock washer between the nut and the work ...

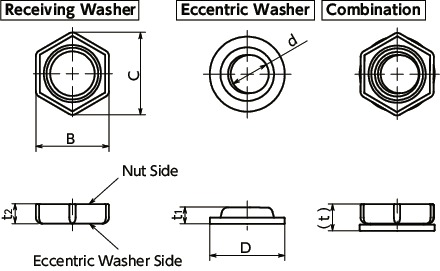

Functional Principle Heico Fastening Systems Heico Lock Wedge Lock Washers Heico Tec Tension Nuts Heico Form Cold Forged Parts Heico Nails Upholstery Nails

Examine your washer's tech sheet to determine which wires to cut. Scan the included wiring diagram until you find the wires labelled "lid switch" and "lock switch." The majority of washing machine lid lock switches are powered by 3 or 4 wires, each of which performs a different function. Hopefully, these will be color-coded.

The lid lock function on your washing machine is important, but sometimes you simply need to override it. There are several ways to bypass this function, including magnets or cutting wires, but it varies based on the brand. Follow along as we explore the few simple ways that you can override the lid lock feature on your washing machine.

Lock washers are designed to secure fasteners that have a tendency to rotate or lose friction. Although though there are several different types of lock washers and is each designed for use with a particular fastener or application, they all work under the same principle. The washer is designed to exert a load, partially deform, and lock a fastener in place. A split coil or teeth of the lock ...

Came here because I wanted to know more about the use of split ring lock washers. I had seen elsewhere that this type of lock washer was ineffective. What a surprise! Have been using them all my life. The order of jam nut and standard nut was a surprise too. Have been using them in the opposite sequence as long as I can remember.

1 Apr 2020 · 3 answersThey gave you four lock washers instead of 4 locking nuts. No problem. Install the bolts as shown in the instructions. Then install a flat ...

Move the wire latch to lock the cuckoo door. Open the back panel and place bellow clips on bellows (see diagram on p. 2). If you cannot locate original bellow clips, fashion a substitute with paper clips to keep the bellows closed and prevent damage during transportation.

0:31lock washer assembly. Watch later. Share. Copy link. Info. Shopping. Tap to unmute. If playback doesn't ...17 Aug 2011 · Uploaded by Michael Freedberg

The Chevrolet Corvair is a compact car manufactured by Chevrolet for model years 1960–1969 in two generations. It remains the only American-designed, mass-produced passenger car with a rear-mounted, air-cooled engine.The Corvair was manufactured and marketed in 4-door sedan, 2-door coupe, convertible, 4-door station wagon, passenger van, commercial van, and pickup truck body styles in its ...

If a lock washer is required, it will be placed on the bolt followed by a second standard washer. Step 3 Align the holes for the joint you are connecting and push the shaft of the bolt through them. The washers should be pressed between the head of the bolt and the material of the joint.

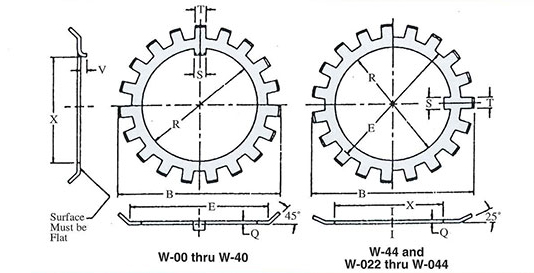

This type of lock washer has many teeth on its outer diameter that cut into a surface and maintain compression. The external tooth lock washer prevents a fastener head from loosening by using the strut action of the teeth. They operate most suitable under large head screws. The external tooth lock washer provides maximum torsional resistance. It is used to lock deep-headed fasteners into place ...

Loose bolts can lead to all kinds of problems in any application. Vibrations are one of the most well-known causes of loose fasteners. So fasteners were made...

China Din2520 9250 Different Types Lock Washers Double Sided Tooth Belleville Spring Self Lock Washer China Nord Lock Washer Sus316l Nord Lock Washer

When you get the world of washers, you cannot deny the convenience they give you when you need to repair your household tools.However, many people, including myself, become confused when attempting to use bolt, nuts, and lock washers - since the differences between the two washers is hard to tell.

Lawnmower manufacturers use screw-on nuts, lock washers and retaining pins to secure mower wheels. Occasionally, it becomes necessary to remove a wheel, perhaps to change it or in the case of a ...

1.Do not use other washers under these specialty lock-washers. Other types of washers will disable the function of the Lock·washer. 2.Ensure that bolt holes, bolt, nut threads and mating surfaces are clean and free of particulate matter, adhesives, lubricants and chemicals. 3.

Differences Between An Internal Tooth Lock Washer & An External Tooth Lock Washer. Tooth lock washers are made with small, sharp teeth formed around the inner hole or outer diameter (O.D.), depending on the type. An internal tooth lock washer has teeth around the center hole, while the external tooth lock washer boasts of teeth around the O.D. Both of these fasteners provide a locking ...

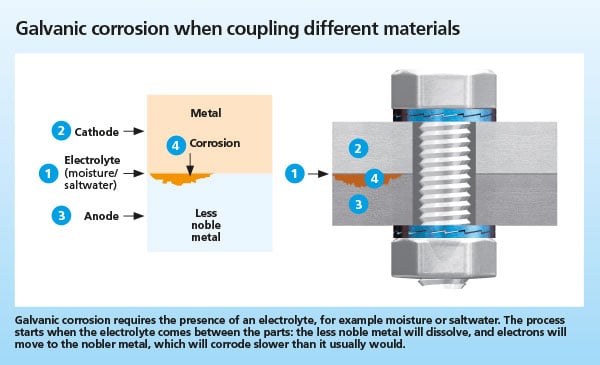

How to use lock washers diagram. Vibration proof locking washers made of other alloys are available as well. So are wedge lock washers for left handed threads. Lock washers are used to keep screws and bolts from loosening especially as a result of vibration or changes in temperature. Im using some star lock washers to keep or at least resist a bolt from backing out. The lock washer grips into ...

1:27Loose bolts can lead to all kinds of problems in any application, and split ring washers aren't the only lock ...17 Sep 2020 · Uploaded by Albany County FastenersMissing: diagram | Must include: diagram

For the same reason, lock washers always go on the nut side to stop the nut moving. Lock washers are almost always used with a flat washer as well. The nut is also often smaller in profile than the bolt head. Not always, but often. The washer helps distribute the pressure that the nut places on the surface of the fastened objects.

>>> When using a nut, lock washer and bolt, should you also use a flat >>> washer between the object and the lock washer? I have seen it done a >>> million times that way but it seems the flat washer defeats the purpose >>> of the lock washer. I assume the lock washer is there to dig in a bit >>> to the object and the nut to keep it from loosening. The flat washer >>> seems like it would allow ...

The jagged side will, to a small degree, bite into the metal of the bolt to increase the holding power. (The majority of the holding power is from just the compression of the lock washer.) Turned the other way will work, just not quite as well. (you don't really care about the washer turning.) Edit: correct my stupid mistake!

Step 1. Place the lock washer between the nut and the work surface if using a nut-and-bolt configuration, or between the fastener head and the work surface if using a tapped hole configuration. In other words, the bolt goes straight into the hole and doesn't poke out the other end, so no nut is used.

In this animated video, we explain the principle behind the Nord-Lock washers. Our original wedge-locking technology secures bolted joints, even when exposed...

The flat washer can be used on the bolt side, nut side or both. If the assembly calls for o ther types of washers or hardware elements besides these two, they should go on before the lock washer. This way the tension created by the lock washer holds them all in place. It is very important that you do not tighten the lock washer too much.

Cmchospitalhisar Com Fasteners Nut Bolt Assortment Sets 10 Sets Stainless Steel Flat Washers Lock Washers Kits Fully Thread Hexagon Bolts Kits 18 8 Nuts Levanco 304 5 16 18x1 Stainless Steel Hex Head Screws Bolts

Serrated Lock Washers Type A External Serrations Serrated Lock Washers Toothed Lock Washers Securing And Anti Loosening Washers Securing And Anti Loosening Elements Fastening Technology Products Bossard Denmark

0 Response to "41 how to use lock washers diagram"

Post a Comment