42 copper zinc phase diagram

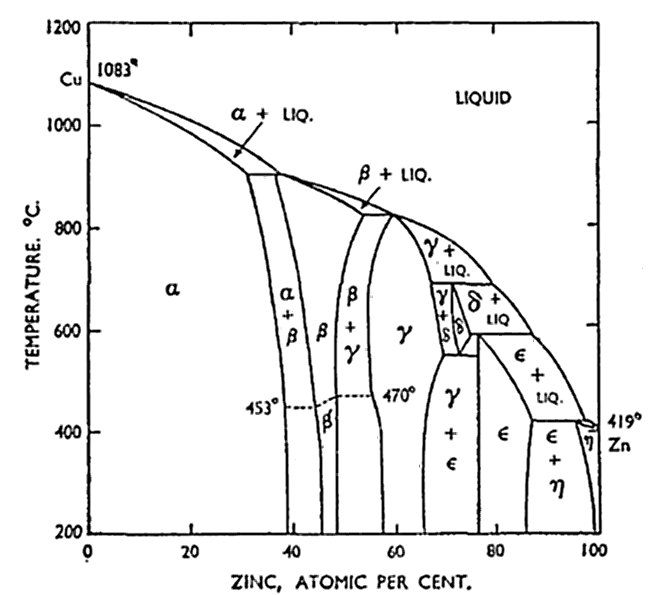

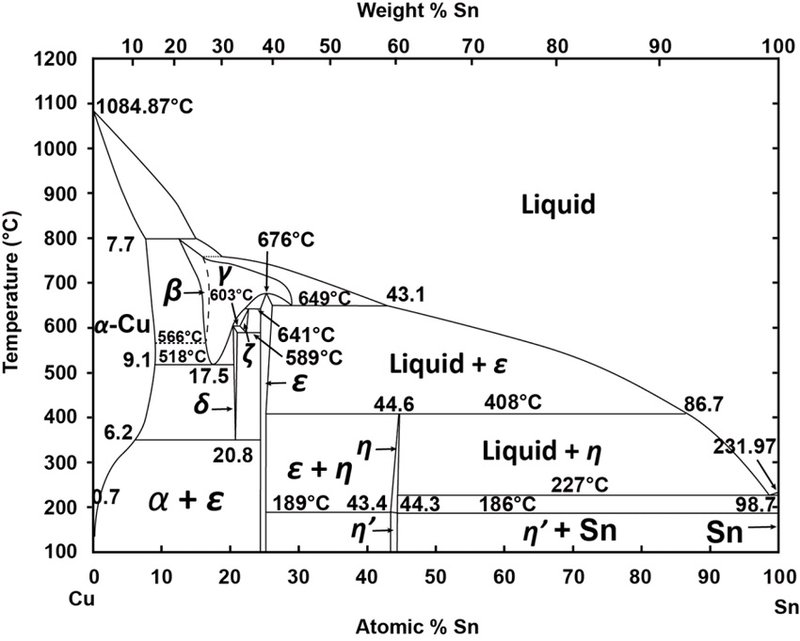

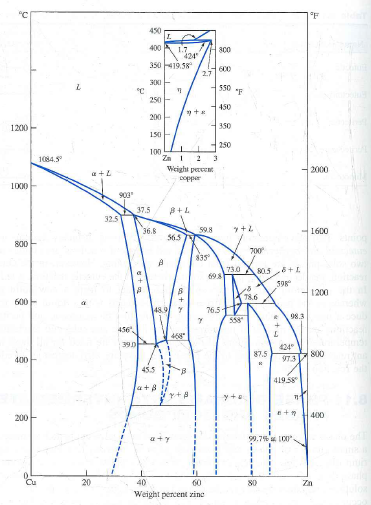

Metals like silver and gold have a difference of 0.2%; nickel and copper of 2.7%, and show complete solid solubility. But zinc and copper have 4.2% difference with maximum solubility of 38.4 wt.% Zn. (other factors are less favourable); Cadmium in copper with 16.5% size difference shows a solid solubility of 1.7 wt.%. This article is a compilation of ternary alloy phase diagrams for which copper (Cu) is the first-named element in the ternary system. The other elements are Fe, Mn, Ni, Pb, S, Sb, Si, Sn, Ti and Zn. The diagrams are presented with element compositions in weight percent.

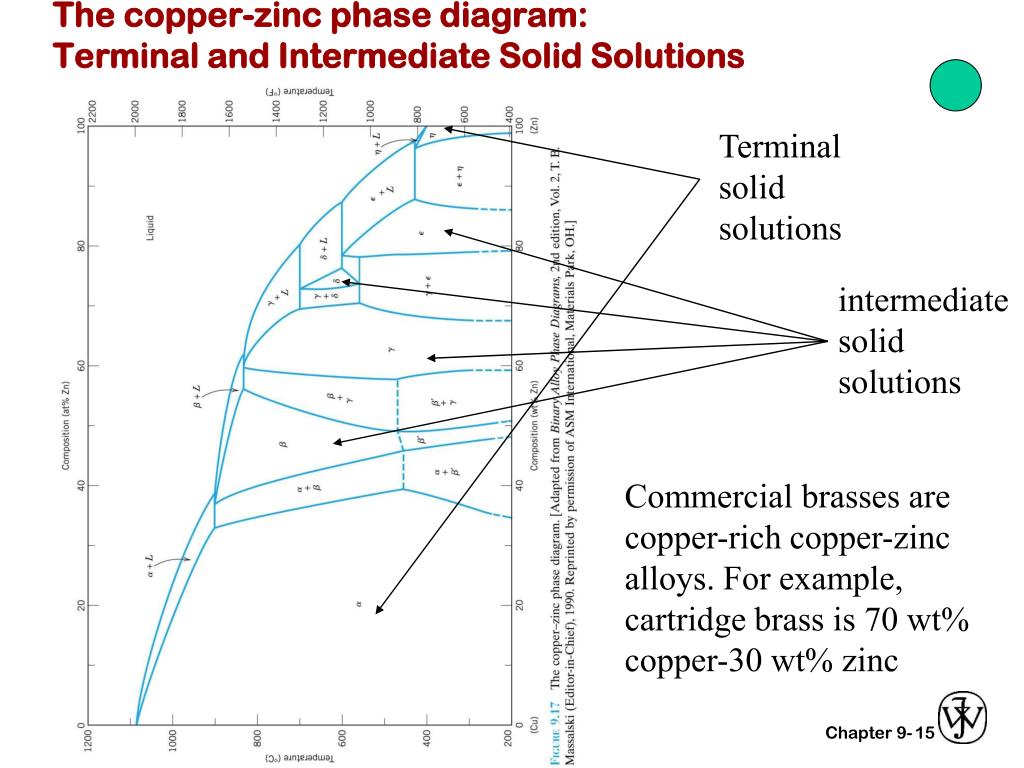

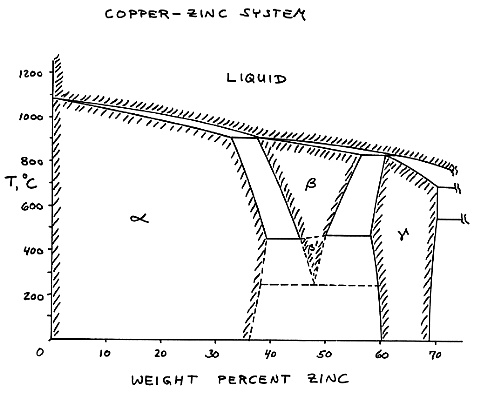

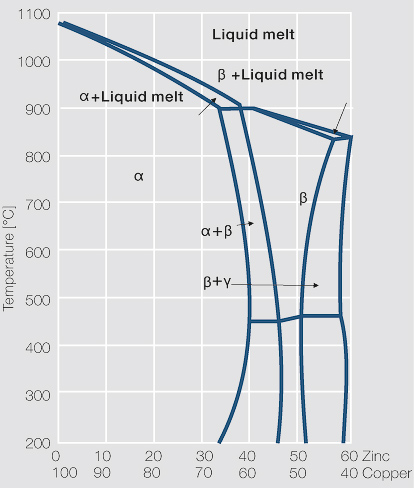

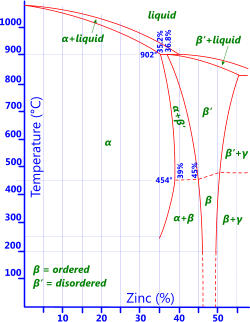

From the copper zinc phase diagram we can see the solid solubility of zinc in copper for concentrations of zinc upto about 30 at at equilibrium the alloy should be of a single phase. Note that each single phase field is separated from other single phase fields by a two phase field. Lecture 19 binary phase diagrams 6 of 16 112305.

Copper zinc phase diagram

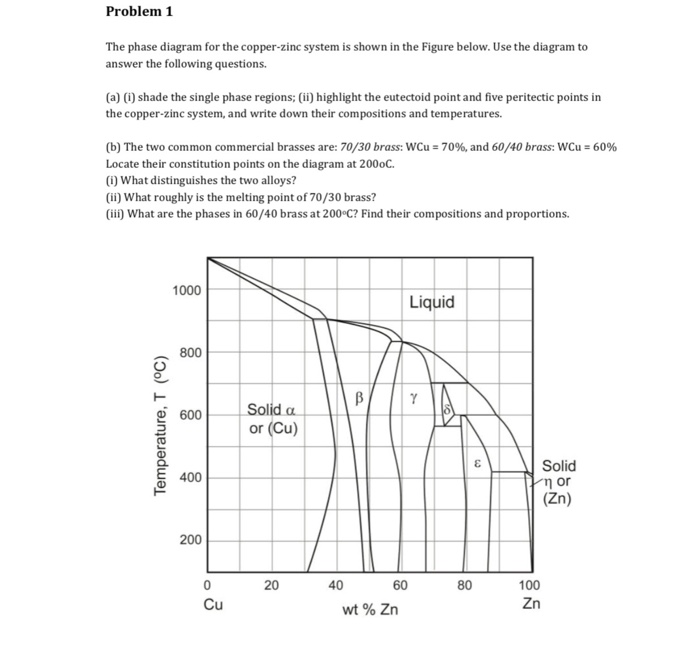

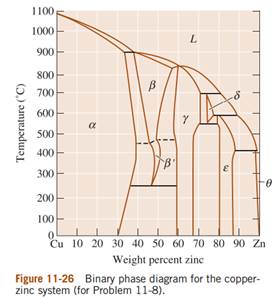

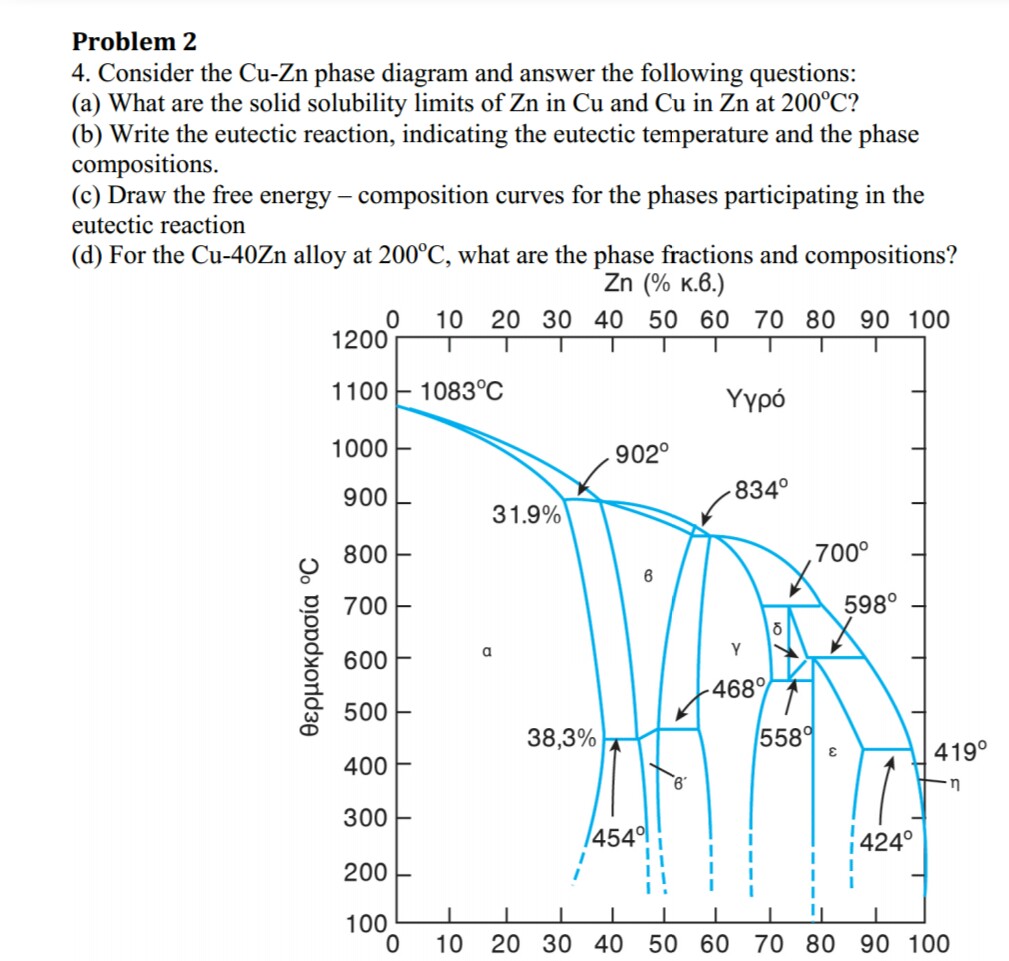

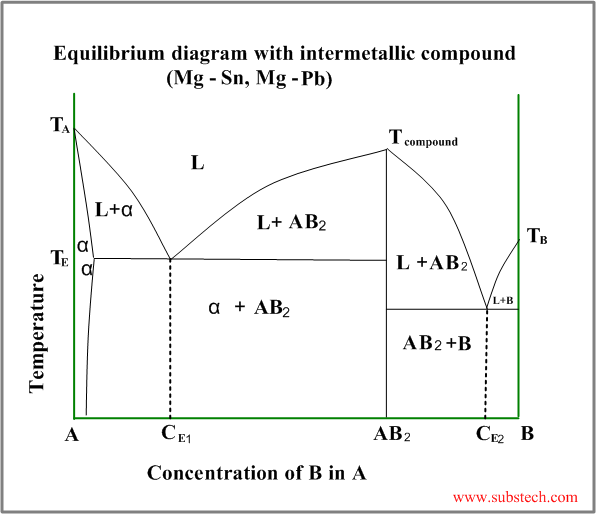

It is 19 wt% Mg-81 wt% Pb. Melting temperature of Mg2Pb 550 oC) Extensive solubility. of the phase diagrams. Eutectic transformation also called eutectic reaction. A eutectic reaction is an invariant reaction, and a eutectic point is also called an invariant point. the horizontal tie line at the eutectoid temperature is termed a eutectoid isotherm. A region of the copper-zinc phase diagram that has been enlarged to show eutectoid and peritectic invariant points , C, 74 wt% Zn) and P (598 C, 78.6 wt% Zn), respectively. Figure by MIT OCW. Note that each single-phase field is separated from other single-phase fields by a two-phase field. Lecture 19 - Binary phase diagrams 6 of 16 11/23/05 Phase Diagram for Cu-Zn. Move the mouse over the phase diagram to view temperature and composition at any point. View micrographs for the Cu-Zn system. List all systems with phase diagrams. 2004-2021 University of Cambridge. Except where otherwise noted, content is licensed under a

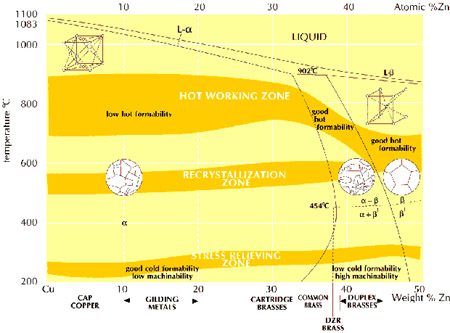

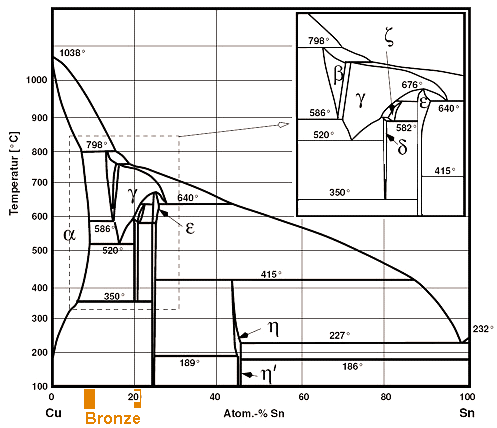

Copper zinc phase diagram. The Diagram of Cu-Si-Zn Alloy-II, Technol. Rep. Osaka Univ., Vol. 7, 1957, p 385-397 Reviewed under the auspices of the Alloy Phase Diagram International Commission. Document includes crystal data for the Copper-Silicon-Zinc system, allotropic transformation data, and related references. Commercial brasses are copper-rich copper-zinc alloys. For example, cartridge brass is 70 wt% copper-30 wt% zinc 15 16 The magnesium-lead phase diagram: like two simple eutectic diagrams joined back to back Intermetallic compound (with distinct chemical formula), NOT a solid solution. Alpha copper is the primary phase in cast alloys containing up to approximately 40% zinc. The beta phase,which is the high zinc phase, is the minor constituent filling in the areas between the alpha dendrites. The microstructure of brasses containing up to approximately 40% zinc consists of alpha dendrites with beta surrounding the dendrites. The copper-zinc phase diagram shown in Fig. 9.2 contains intermedi-ate phases with appreciable ranges of solid solubility. In this diagram, the copper-rich α solid solution and the zinc-rich η solid solution are the two terminal phases, and the four intermediate phases are β, γ, δ, and ε. The

Download scientific diagram | Phase diagram of the copper-zinc system [17]. from publication: Cu-Zn powders as potential Cr(VI) adsorbents for drinking water | This work examines the possibility ... The alloy consists of the face centred cubic alpha phase, and has the optimum combination of strength and ductility in the copper-zinc series. C26000 has the distinctive clear bright yellow colour normally associated with 'brass'. ... Phase Diagram & Mechanical Properties . Phase Diagrams • Indicate phases as function of T, Co, and P. • For this course:-binary systems: just 2 components.-independent variables: T and Co (P = 1 atm is almost always used). • Phase Diagram for Cu-Ni system Adapted from Fig. 9.3(a), Callister 7e. (Fig. 9.3(a) is adapted from Phase Diagrams of Binary Nickel Alloys , P. Nash Brass Phase Diagram. some phase diagrams technische fakultät the copper zinc phase diagram is a bit simpler than the copper tin phase diagram but still plex enough there are all kinds of brass but typically doitpoms tlp library microstructural examination brasses brasses are copper alloys with zinc see the cu zn phase diagram alpha brass from the copper zinc phase diagram we can see the solid ...

Download scientific diagram | Copper Zinc Phase diagram (I. Macleod after Lyman et al. 1973). from publication: Preliminary analysis of copper alloy fastenings from an unidentified shipwreck in ... The diagram consists of two single phase fields separated by a two phase field. For the copper zinc system print out the phase diagram and show all work for the following questions. The boundary between the liquid field and the two phase field in fig. Lecture 19 binary phase diagrams 6 of 16 112305. A at 55wt zinc and 600oc tell me what phases ... Zinc: As can be seen from the phase diagram in Fig 2 copper will support limited levels of zinc at any given temperature before the base metal becomes saturated and no longer behaves like an alloy. The Copper (Cu) - Zinc (Zn) equilibrium phase diagram for 200g Cu-54wt% Zn alloy and 300g Cu -80wt% Zn is given in Figure 1. The temperature at Point A and Point C are just above 900 °C and 600°C, respectively. Zing, at.% 50 10 20 30 40 60 70 80 90 1100 2000 CL 1000 903 1800 1083 °C L B+L 900 1600 a+ BOO 1400 TARDE Temperature, °C 700 660 ...

Constitutional Diagram of the Copper-Zinc Alloys. The addition of zinc to copper results in the formation of a series of solid solutions which, in accordance with usual practice, are referred to in order of diminishing copper content as the a, b, g, etc., constituents. The diagram may be summarized as follows:

Copper Development Association Equilibrium Diagrams Selected copper alloy diagrams illustrating the major types of phase transformation CDA Publication No 94, 1992

The copper - zinc phase diagram is a bit simpler than the copper - tin phase diagram but still complex enough. There are all kinds of brass' but typically we are at the copper-rich side. Of course, if we want to look at all copper alloys, we would need a bunch of more binary phase diagrams, in particular for the elements arsenic (As), antimony, (Sb), silver (Ag), and lead (Pb) since these are ...

Phase Diagram Bi-Sn By: Seth Van Grinsven Chris Wenrich ENGR 45 Fall 2011. Resistivity vs %wt Concentration ... 21 Total Samples Make Wire Measure Resistance Calculate (ρ) Bismuth (Wt %) Tin (Wt %) Zinc (Wt %) 100 0 0 0 100 0 0 0 100 0 80 20 0 60 40 0 40 60 0 20 80 20 80 0 20 60 20 20 40 40 20 20 60 ... Copper) Small Rise when going from one ...

Phase Diagrams: Brass · The Copper-Zinc binary phase diagram () is another example of a complex phase diagram which shows many invariant reactions. · Two common alloy compositions are shown, Cartridge brass (red) which is Cu-30 wt % Zn, and Muntz metal (green) Cu-40 wt % Zn.: From: Guy and Hren, "Elements of Physical Metallurgy," Addison Wesley (1974)

The single phase alpha brasses, containing up to about 37% zinc, are very ductile and easy to cold work, weld and braze. The dual phase alpha-beta brasses are usually hot worked. There are many brasses, with properties tailored for specific applications by the level of addition of zinc. Minor amounts of other alloying elements may also be added.

Previous Next Copper based alloys. Brasses: Brasses are copper alloys with zinc, see the Cu-Zn phase diagram.. Alpha brass: From the copper-zinc phase diagram we can see the solid solubility of zinc in copper, for concentrations of zinc upto about 30 at.%, at equilibrium the alloy should be of a single phase.

E.10 The phase diagram for the copper-zinc system (which includes brasses) is shown in Figure GL2.19. Use the diagram to answer the following questions. (a) (i) Shade the single-phase regions. (ii) Highlight the eutectoid point and five peritectic points in the copper-zinc system, and write down their compositions and temperatures.

Design Biodegradable Zn Alloys Second Phases And Their Significant Influences On Alloy Properties Sciencedirect

system, the phase diagram usually has the general appearance of that shown in Fig. 3. The diagram consists of two single-phase fields separated by a two-phase field. The boundary between the liquid field and the two-phase field in Fig. 3 is called the liquidus; that between the two-phase field and solid field is the solidus.

Alloys with a High Content of Zinc This chapter considers the phase composition of alloys that contain zinc and magnesium as obligatory components. Many of these alloys also contain copper; therefore, the Al-Mg-Zn and Al-Cu-Mg-Zn phase diagrams are basic for this group of alloys, which includes mainly wrought alloys of the 7XXX series, e.g. high-

Reliability Investigation Of The Copper Zinc System For Solid Diffusion Bonding In Power Modules Sciencedirect

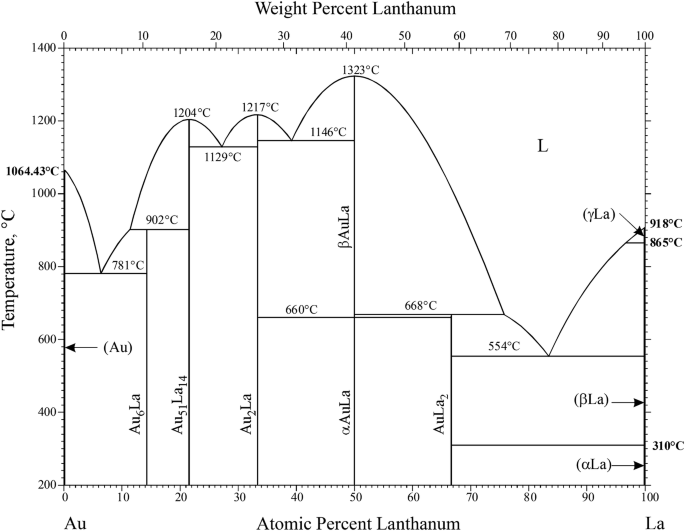

Teach Yourself Phase Diagrams A.1 HRS 03/11/2009 and Phase Transformations ... concentrations of copper and zinc in the -brass, in at%, X Cu and X Zn. E.2 A special brazing alloy contains 63 wt% gold (Au) and 37wt% nickel (Ni) (which is written Au-37wt% Ni). The atomic weight of Au (197.0) is more than three times that of Ni (58.7).

Phase Diagram for Cu-Zn. Move the mouse over the phase diagram to view temperature and composition at any point. View micrographs for the Cu-Zn system. List all systems with phase diagrams. 2004-2021 University of Cambridge. Except where otherwise noted, content is licensed under a

A region of the copper-zinc phase diagram that has been enlarged to show eutectoid and peritectic invariant points , C, 74 wt% Zn) and P (598 C, 78.6 wt% Zn), respectively. Figure by MIT OCW. Note that each single-phase field is separated from other single-phase fields by a two-phase field. Lecture 19 - Binary phase diagrams 6 of 16 11/23/05

It is 19 wt% Mg-81 wt% Pb. Melting temperature of Mg2Pb 550 oC) Extensive solubility. of the phase diagrams. Eutectic transformation also called eutectic reaction. A eutectic reaction is an invariant reaction, and a eutectic point is also called an invariant point. the horizontal tie line at the eutectoid temperature is termed a eutectoid isotherm.

Figure 1 The Effects Of Adding Elements Of Zinc And Magnesium On Ag Cu Eutectic Alloy For Warming Acupuncture

Ppt The Copper Zinc Phase Diagram Terminal And Intermediate Solid Solutions Powerpoint Presentation Id 5577618

Scielo Brasil Effects Of Composition And Thermal Treatment Of Cu Al Zn Alloys With Low Content Of Al On Their Shape Memory Properties Effects Of Composition And Thermal Treatment Of Cu Al Zn Alloys With

Chapter 9 15 The Copper Zinc Phase Diagram Terminal And Intermediate Solid Solutions Terminal Solid Solutions Intermediate Solid Solutions Commercial Ppt Download

Supplemental Literature Review Of Binary Phase Diagrams Au La Ce Pt Co Pt Cr S Cu Sb Fe Ni Lu Pd Ni S Pd Ti Si Te Ta V And V Zn Springerlink

0 Response to "42 copper zinc phase diagram"

Post a Comment