40 process control block diagram

A process control block (PCB) contains information about the process, i.e. registers, quantum, priority, etc. The process table is an array of PCB’s, that means logically contains a PCB for all of the current processes in the system. Pointer – It is a stack pointer which is required to be saved when the process is switched from one state to ... Introduction •A Block Diagram is a shorthand pictorial representation of the cause-and-effect relationship of a system. •The interior of the rectangle representing the block usually contains a description of or the name of the element, gain, or the symbol for the mathematical operation to be performed on the input to yield the output.

BLOCK DIAGRAM OF PCB 5 6. PROCESS CONTROL BLOCK (PCB) PCB consist of following information~ Pointer . Process state . Program counter . CPU register . CPU scheduling information . Memory management information . Accounting information . I/O status information . 6 7.

Process control block diagram

•The block labeled "control valve" has p(t) as its input signal and w 2 (t) as its output signal, which illustrates that the signals on a block diagram can represent either a physical variable such as w 2(t) or an instrument signal such as p(t). A block diagram of feedback control looks like a loop: The reason any control system is necessary at all 1000 to maintain a process variable at some stable value is the existence of something called a load. Structure of the Process Control Block The process control stores many data items that are needed for efficient process management. Some of these data items are explained with the help of the given diagram − The following are the data items − Process State This specifies the process state i.e. new, ready, running, waiting or terminated.

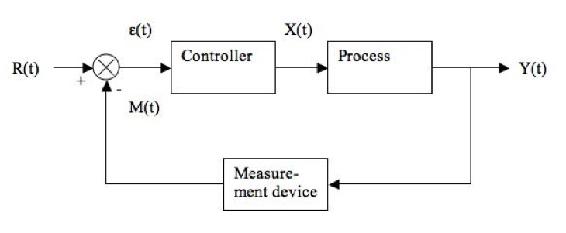

Process control block diagram. The figure shows the block diagram of close loop system or process control system. The process control system consists of process or plant, feedback elements, error detector, automatic controller, actuator or control element. Block diagram – process control system Plant or Process : Process Control block is used for storing the collection of information about the Processes and this is also called as the Data Structure which Stores the information about the process. The information of the Process is used by the CPU at the Run time. The various information which is Stored into the PCB as followings: 1) Name of the Process. ConceptDraw flowchart maker allows you to easier create a process flowchart. Use a variety of drawing tools, smart connectors, flowchart symbols and shape libraries to create flowcharts of complex processes, process flow diagrams, procedures and information exchange. Process Control Block Diagram feedback control - 8.7 8.3.2 Manipulating Block Diagrams A block diagram for a system is not unique, meaning that it may be manipulated into new forms. Typically a block diagram will be developed for a system. The diagram will then be simplified through a process that is both graphical and algebraic. For exam-

The process control block is identified by an integer process ID. (PID) and PCB keep all the information needed to keep track of a process. Diagram of a Process Control Block (PCB). - a data structure used in the OS code to represent one process. - the set of PCB s is called the process table. Oct 23, 2018 · Process Control Block Diagram. Process control block diagram in the operating system is an important concept related to processing. In the previous process concepts tutorial, we have learned about different basics concepts of the process such as the basic introduction of process, abstract view of the process in memory or process architecture, and process state diagram. Process management involves various tasks like creation, scheduling, termination of processes, and a dead lock. The important elements of Process architecture are 1)Stack 2) Heap 3) Data, and 4) Text. The PCB is a full form of Process Control Block. It is a data structure that is maintained by the Operating System for every process.

A block diagram of a simple discrete control system is shown in below figure. The devices used to sense system conditions in discrete control are typically electrical switches, with contacts that are open when the variable is in one state and closed when it is in the other. Figure : Discrete control system block diagram Block diagrams are different than a process diagram in that it is a diagram of the flow of information, not necessarily how the pieces of equipment are physically placed. Control Terminology There is different terminology when talking about common controllers such as Proportional Integral Derivative (PID) or advanced controllers such as Model ... Block diagrams consist of a single block or a combination of blocks. These are used to represent the control systems in pictorial form. Basic Elements of Block Diagram The basic elements of a block diagram are a block, the summing point and the take-off point. A Process Control Block or simple PCB is a data structure that is used to store the information of a process that might be needed to manage the scheduling of a particular process. So, each process will be given a PCB which is a kind of identification card for a process.

Recap In the last class, you have learnt • Process, Process State Diagram • Sequential Process 2 3. Objectives On completion of this period, you would be able to know • Understand the Structure of Process Control Block 3 4. Process Control Block • Each process is represented in the operating system by a Process control block ( PCB ...

Open Loop System Block Diagram Set point The set point is the input that determines that the desired operating point of the process. Controller Makes the system's decision based on the input signals, generates output signals, which operate actuators to carry out the decision. Actuators

Process Control Block is a data structure that is maintained by the operating system. PCB maintains the specific information, about the process, which is helpful while its execution. As soon as the process is created it is the responsibility of the operating system to create a respective process control block for it.

The traditional block diagram for cruise control (click for a large view) is thus: Instruments Should be Fast, Cheap and Easy The above magnet and coil "click rate = car speed" example introduces the idea that when purchasing an instrument for process control, there are wider considerations that can make a loop faster, easier and cheaper to ...

A simple control system drawn in block diagram form looks like this: Information from the measuring device (e.g. transmitter) goes to the controller, then to the final control device (e.g. control valve), influencing the process which is sensed again by the measuring device.

Dec 08, 2021 · A block diagram majorly comprises rectangle shapes known as blocks and the straight lines with arrows at the end. While the blocks represent the key elements of the entire process, the arrowed lines show the relationship between the two objects and the direction the data, information, processing, signals, or the electric current flows in.

Block diagrams are a flow chart of signals and transfer functions that relate inputs to outputs. The dynamic response of the outputs can be simulated by piec...

A process control block ( PCB) is a data structure used by computer operating systems to store all the information about a process. It is also known as a process descriptor. When a process is created (initialized or installed), the operating system creates a corresponding process control block.

Ankh...Secret of the Ankh...Ancient Egyptian Sexual Ankhing..(located above the sternum), with your willpowerfirst key to the Mysteries “The Creation of Everythingâ€..

A block diagram is used to represent a control system in diagram form. In other words, the practical representation of a control system is its block diagram. Each element of the control system is represented with a block and the block is the symbolic representation of the transfer function of that element.

A block diagram representation in which there is only one forward and feedback block along with a single summing point and take-off point is the simplest form of closed-loop control system. It is also known as the canonical form of a closed-loop system. The figure below shows a simple closed-loop system: Example of Control System

The equivalent block diagram is shown below. Similarly, you can represent the positive feedback connection of two blocks with a single block. The transfer function of this single block is the closed loop transfer function of the positive feedback, i.e., $\frac{G(s)}{1-G(s)H(s)}$ Block Diagram Algebra for Summing Points

7/00 Process Control Primer iii About This Publication The automatic control of industrial processes is a broad subject, with roots in a wide range of engineering and scientific fields. There is really no shortcut to an expert understanding of the ... Figure 1-3 Block diagram of system with operator.....5 Figure 1-4 Block Diagram of System with ...

Process Control Technicians are in high demand in industry. As automation continues to advance our capabilities, it also increases the difficulty of maintaining the system. Understanding the complex systems in automation begins with the basics, such as print reading. A block diagram is a pictorial representation of the cause and effect relationship between the input and output of

Process Controls PRINCIPLES OF CONTROL SYSTEMS PRINCIPLES OF CONTROL SYSTEMS Control systems integrate elements whose function is to maintain a process variable at a desired value or within a desired range of values. EO 1.1 DEFINE the following process control terms: a. Control system b. Control system input c. Control system output d. Open ...

Block diagrams help us visualize the components of a loop and see how the pieces are connected. Closed Loop System Working Animation A home heating system can be a simple on/off control or a proportional control by adjusting the amount of hot fluid by throttling a control valve.

Structure of the Process Control Block The process control stores many data items that are needed for efficient process management. Some of these data items are explained with the help of the given diagram − The following are the data items − Process State This specifies the process state i.e. new, ready, running, waiting or terminated.

A block diagram of feedback control looks like a loop: The reason any control system is necessary at all 1000 to maintain a process variable at some stable value is the existence of something called a load.

•The block labeled "control valve" has p(t) as its input signal and w 2 (t) as its output signal, which illustrates that the signals on a block diagram can represent either a physical variable such as w 2(t) or an instrument signal such as p(t).

Night Time, Water Reflection, Washington Monument, Washington, District Of Columbia, United States Of America.

Monochrome, Unesco World Heritage Site, National Trust, Water Landscape, Giant's Causeway, County Antrim, Northern Ireland.

This home’s interior, though beautiful, houses a potential hazard on many levels, therefore, special care need be taken in order to safely operate this wood-burning stove, for not only does it generate a terrific amount of heat, it does so using flame, rather than electricity, which is much more difficult to control. This man was about to place what appears to be a piece or treated lumber into the stove as fuel.

0 Response to "40 process control block diagram"

Post a Comment