45 small block chevy oiling system diagram

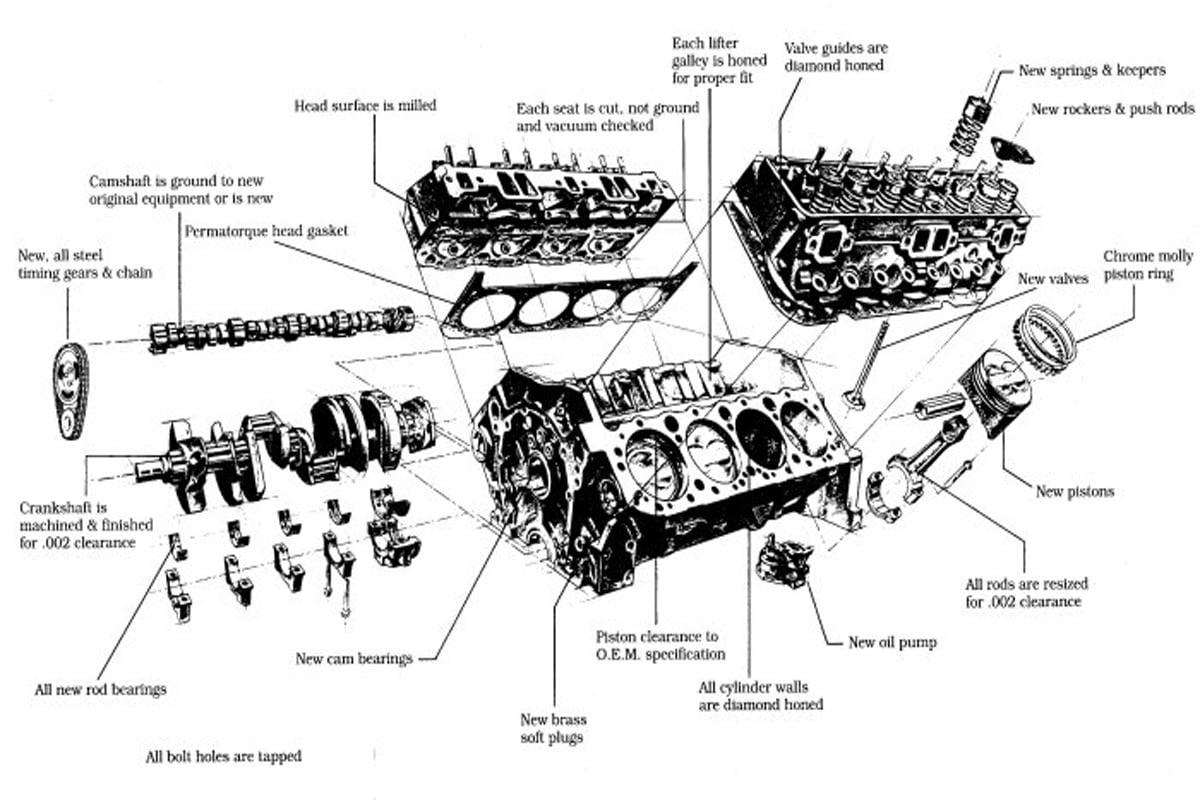

World Products SBC Cast Iron Engine Block Chevy Small Block 350 Mains, 9.025″Deck, 3.995″ Bore, Nodular Caps. Standard Cam 084010. World Products has developed a refined version of its popular MOTOWN block in the form of the MOTOWN II, and now offers it in over two dozen iterations for small block Chevrolet applications. Priority main oiling system Main bearing bulkheads are .900-inch thick and use Grade-8 bolts All five cam bearing locations require 2.000-inch O.D. (1.867-inch I.D.) bearings P/N 12370843 (except block P/N 10051183)

"Factory Ford (Windsor block family) and Chevy (big block and small block) engines are all different in the volume of oil they can move and the volume of oil they really need in the different areas of the engine," says Scheel. "As a result, changes we apply in our blocks are not one-size-fits-all.

Small block chevy oiling system diagram

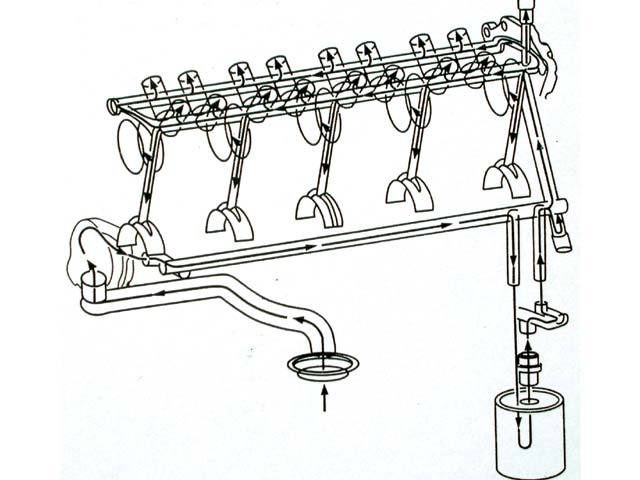

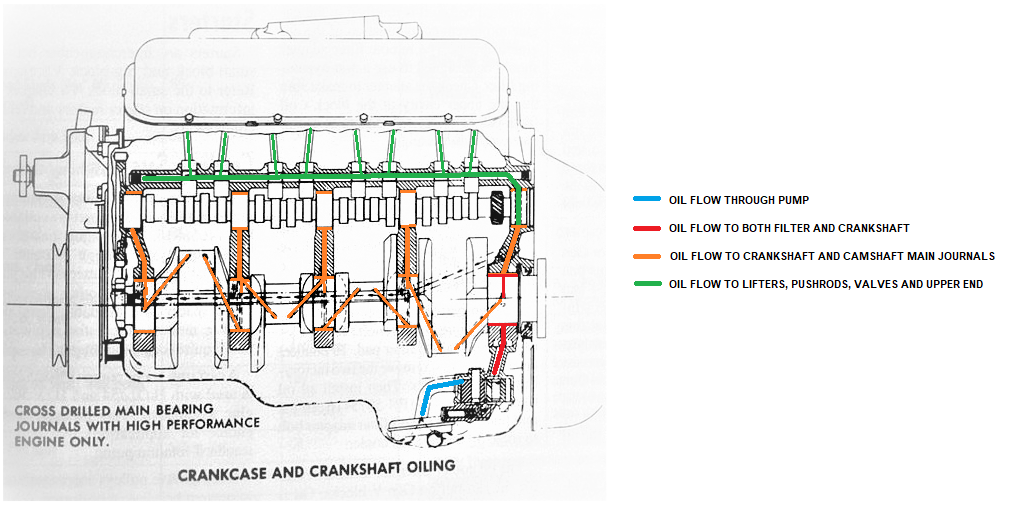

On the small-block engine, the distributor is an integral part of the oiling system. The distributor body has a groove around it through which oil flows to both heads. The Speedmaster oil primer (it replaces the distributor and spins the oil pump) also has this groove, and if it's pushed all the way in, that should allow oil to flow to both ... The oiling system is actually involved with every part in the engine assembly. Many of the paths that the oil takes from one part to another are in the block and the crank. The oil also lubricates the cam, tappets, valves, rocker arms, pistons, rods. Rocker arms and valve tips are the most difficult parts to properly lubricate. In this video, I will show where the forgotten oil galley plug is located on a small block Chevy. This oil galley plug is very easily overlooked and quite of...

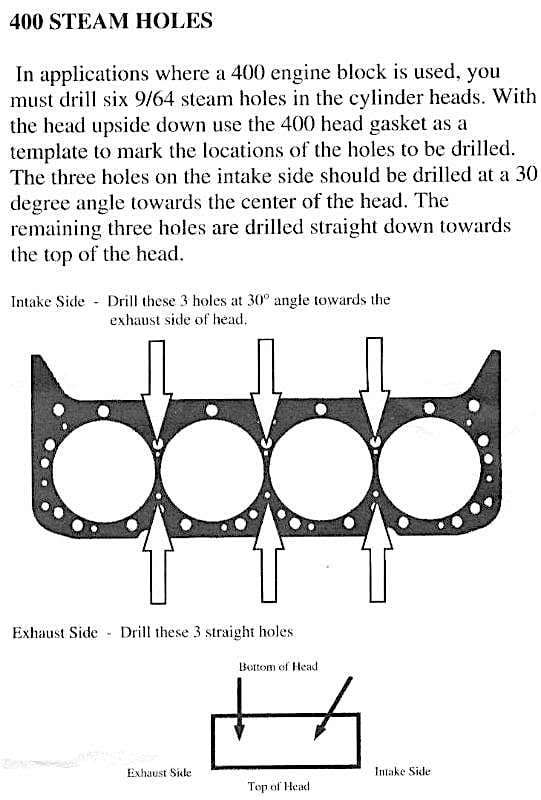

Small block chevy oiling system diagram. All small block Chevy engines were produced with an annular groove under the rear cam bearing regardless of what year they are. This groove supplies oil to the two lifter galleries. The difference in the 55-56 engines is in how the oil is supplied to the groove. Oil system: Wet Sump - Main Priority Oiling Oil Pump shaft: 350 main = Stock shaft (.481" OD) Oil Filter: Standard SBC filter, uses 2 bolt filter adapter Oil Pan: Standard 1980-1985 SBC oil pan Rear Main Seal 350 main - std seal Serial No. Left front & main caps Starter: Standard SBC First, it was the only small-block that Chevrolet made with 4.125-inch bores as opposed to the by-then-common 4-inch bore. To achieve the 4.125-inch bores, some internal casting changes were done. This block usually is recognizable by the fact that most of them have three freeze plugs in the outside of the block rather than two. World Products has combined the two designs to build an engine block that uses the traditional small-block Chevrolet footprint but makes use of the LS top end.This strategy allows hot rod owners and other enthusiasts to take advantage of the low entry cost of SBC hard parts and the large improvements seen by the LS induction system in one slick package.

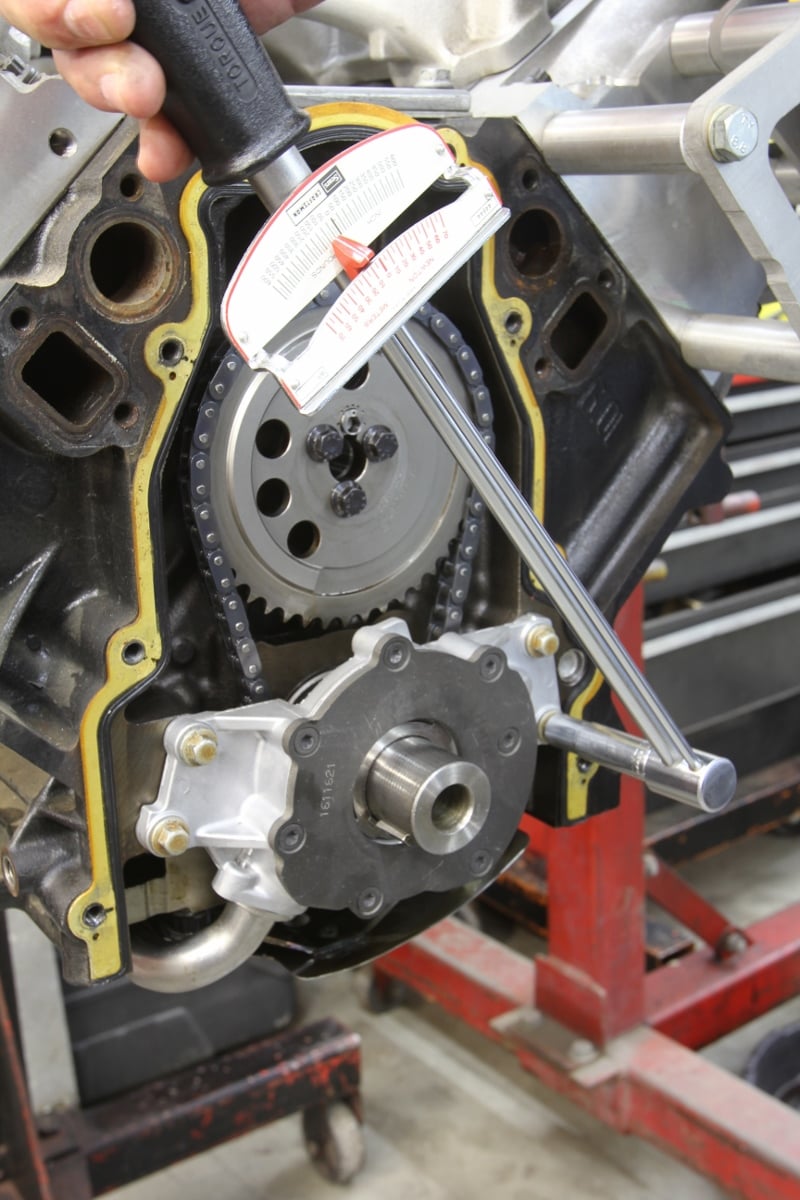

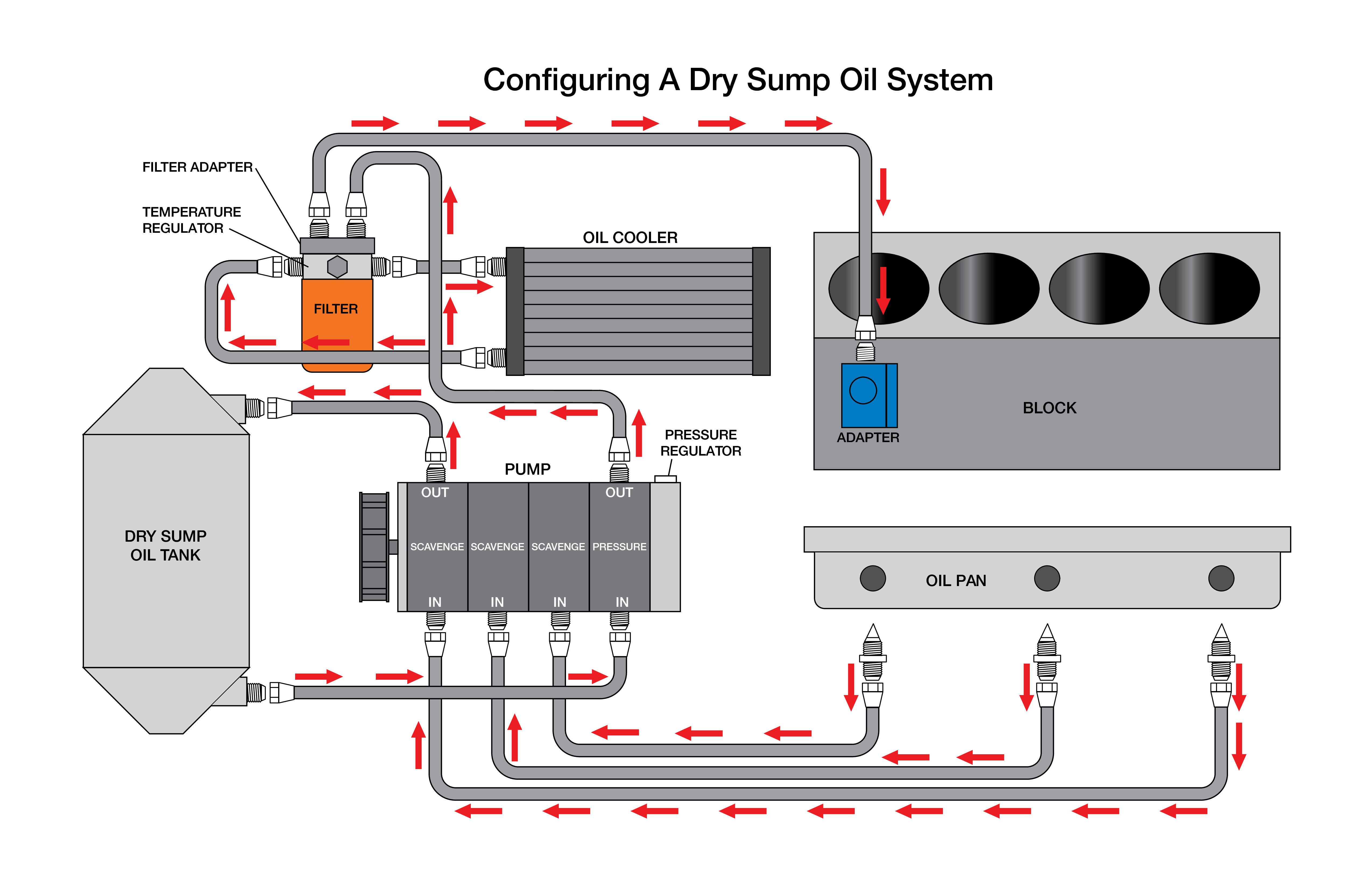

We used my old 350 block to pop the rear cam plug, front and rear cam bearings, and oil galley plugs out of the block to see where oil gets routed. I found that oil comes from the filter, to the pressure tap where the oil pressure gauge is tapped into the back of the block and that also taps into a hole in the main galley about 2 inches from ... Priority Main Oiling. Most OEM and aftermarket race cylinder blocks are configured for priority main oiling to protect the main bearings at high RPM. This oiling strategy gives priority to directly oiling the main bearings first. Pressurized oil within the main oil gallery follows a direct path to each main bearing first as seen in this photo ... The LS-D oil pump system comes with a choice of three-different oil pans; a modified LS2 cast pan, an ARE cast aluminum pan or a stamped steel pan with louvered windage tray. Going off the sheet, we opted to go a different route and chose Aviaid's LS, 5-port, billet, dry sump oil pan (Part #152-52505) that gave us low profile and some options ... oiling system • primary oiling system • when using raised cam block, oil pump shaft must be modified or spacer must be installed under wet sump oil pump. (.350 thick) • remote oil filter only. replacement part numbers www.brodix.com • 301 maple avenue • p.o. box 1347 • mena, ar 71953

235 Rocker Oiling Evolution. 1953-57 full pressure 235's (full pressure started in 1953 in the Powerglide cars) had a 1/16" oil restrictor fitting which screwed into the block at the beginning of the rocker oil supply tube under the side cover. They also used a rocker connector that looped over the top and then dumped excess oil back on the ... Crankshaft Coalition Wiki -- hot rod tech articles The best place to start examining the small-block oiling system is at the oil pump. The factory now offers only one oil pump for production small-blocks: the Z28 pump PN 3848907. This bulletproof pump has 1.20-inch tall gears and is standard equipment on all small-block engines. This system mounts the pump directly to the block and includes a modified LS2 cast oil pan and drive belt and allows you to remove the factory oil pump. The company's LS-A system is designed for street and mild competition use. It uses the factory crankshaft-mounted pump to provide the oil pressure, then changes out the rest of the oiling ...

When a wet sump oiling system is used, a BBC oil pump driveshaft is needed. Timing cover and Oil pump dowel pins are .246" O.D. in dart blocks Note: Be sure to check distributor to oil pump shaft clearance with distributor, intake manifold and oil pump installed on block.

Most stock small-block Chevy pumps deliver oil pressure between 35 and 45 psi. Most are right around the 40-psi mark. On occasion, changing to synthetic oil on an engine with the pressure relief valve at the lower mark will cause the oil pressure to drop as much as another 5 psi.

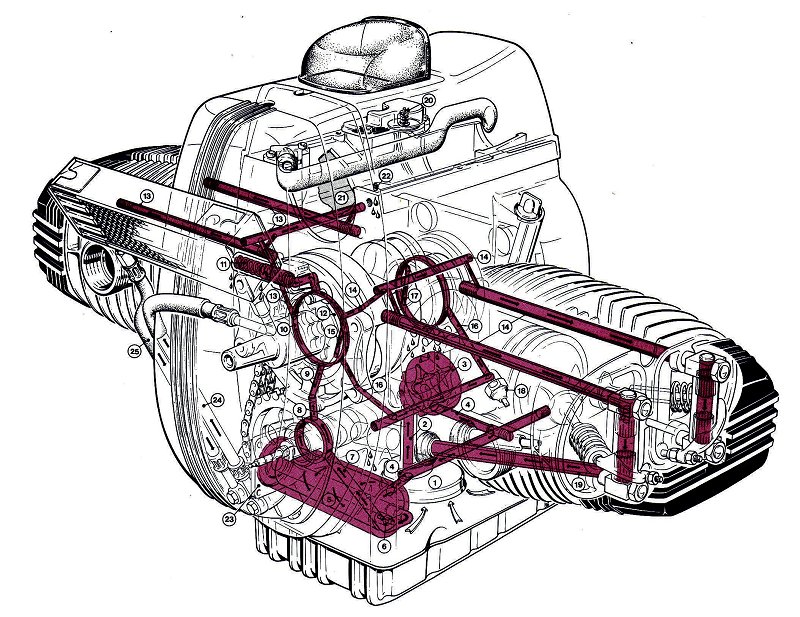

Dry Sump Chevy small block. Dry Sump system for the Chevy small block engine. > Click image to enlarge. TOTAL: 1 - files. File: Chevy small block with pump. Size: 29 KB. Download.

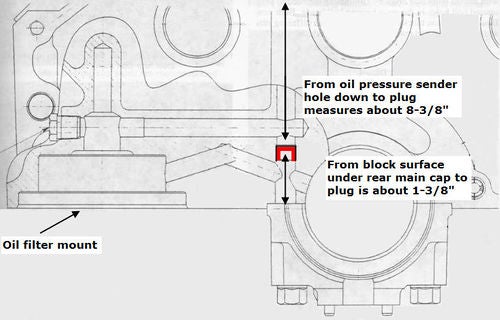

DRY SUMP SYSTEM If a dry sump oiling system is used you must plug the inlet hole in the rear main cap or the hole in the block underneath the rear main cap. Block has threaded inlets for dry sump oil feed in front or rear of block. Block has boss provided for dry sump scavenge in the valley area. Hole must be drilled & tapped for valley scavenging.

Re: Small Block Chevy Oiling System « Reply #11 on: December 15, 2006, 05:11:51 AM » if i remember correctly small block dist with the point and condenser system would interchange-i believe there was a short and longer shaft dist but that was in the 1950s-that was a cast iron housing version.

small block Chevy oil flow diagram. Thread starter bobs409; Start date Jul 16, 2012; bobs409 . Administrator. Jul 16, 2012 #1 I tried searching Google for this and did find a few diagrams but they are hard to follow. Can anyone descibe the path the oil takes starting after it gets sucked up the oil pickup tube? Someone here mentioned the small ...

BANNED. 3 above the cam plug at rear of block, 3 behind cam sprocket, 1 at 10-11 O Clock outboard of the timing cover, 1 above the oil filter boss, and 1 on rear part of driver's deck surface (part covered by head and gasket-easily overlooked). And I believe 1 internal that's near the rear main web that forces oil to the filter.

While oil pumps and pickups may not be as romantic as cylinder heads and camshafts, the engine still needs a well-designed oiling system to live a long and powerful life. Perhaps the most dramatic LS engine architecture change was away from the traditional Gen I small-block Chevy oil pump.

Chevy Big-Block Performance: Lubrication System Guide. In a Chevy big-block, it's essential to maintain not just oil pressure but also oil control. Controlling where the oil goes in the engine can be an issue even for a nearly stock engine turning moderate RPM. When the RPM climbs, this situation really demands attention.

Oil goes from the oil pump to the lifter galleys. I wonder if one of the galley plugs came out ? Hard for that to happen on a big block becsaue they are all threaded in. Did it lose oil pressure, or just get noisy ? I have an oiling system diagram at the shop I can send on Monday.

If oil is the lifeblood of your engine, then the oil pump and lubrication system are indeed the heart and circulation system of your big-block Chevy. For power levels up to about 500 hp, there's really not much that needs changing, other than to ensure that your parts are up to spec, and that the lubricant you are using is the right choice ...

In this video, I will show where the forgotten oil galley plug is located on a small block Chevy. This oil galley plug is very easily overlooked and quite of...

The oiling system is actually involved with every part in the engine assembly. Many of the paths that the oil takes from one part to another are in the block and the crank. The oil also lubricates the cam, tappets, valves, rocker arms, pistons, rods. Rocker arms and valve tips are the most difficult parts to properly lubricate.

On the small-block engine, the distributor is an integral part of the oiling system. The distributor body has a groove around it through which oil flows to both heads. The Speedmaster oil primer (it replaces the distributor and spins the oil pump) also has this groove, and if it's pushed all the way in, that should allow oil to flow to both ...

0 Response to "45 small block chevy oiling system diagram"

Post a Comment