44 stainless steel phase diagram

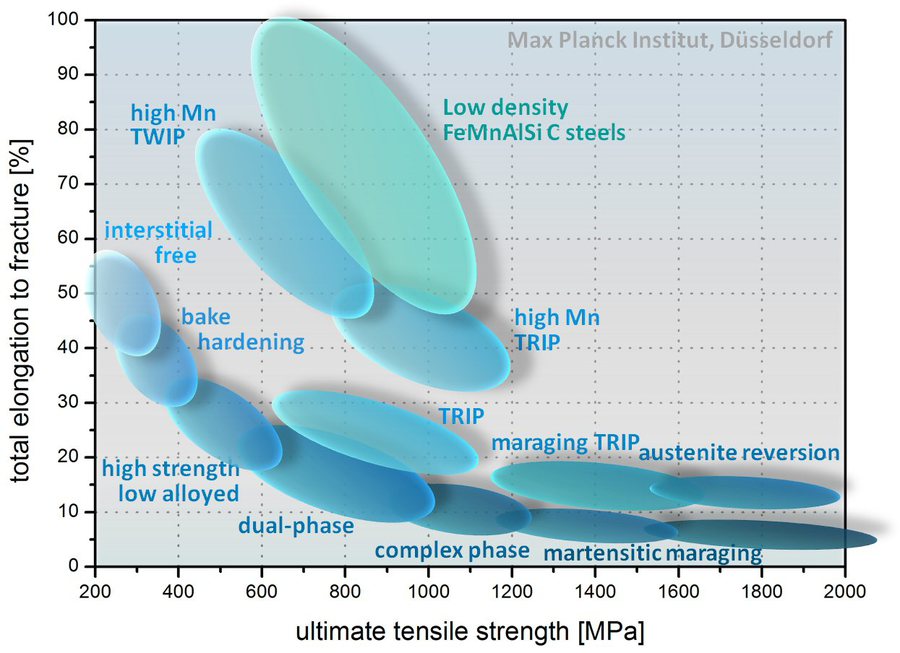

Metallography of Steels - University of Cambridge The phase diagram illustrates the domains in which particular phases or combinations of phases are stable, and contains information about their equilibrium compositions. Equilibrium phase fractions can also be estimated from a knowledge of the carbon concentration of the steel and an application of the lever rule. PDF Stainless Steels: An Introduction to Their Metallurgy and ... Figure 1. Crystal structures of stainless steels Figure 2. The influence of chromium on the atmospheric corrosion of low carbon steel Ferrite is the basic crystal struc-ture of iron or low-alloy steel at am-bient temperatures. To understand it, envision a cube with an atom at each of the eight corners and in the geo-metric centre of the cube ...

PDF Stainless Steel 316/316l (UNS S31600) Stainless Steel 316 has superior corrosion resistance properties as well as elevated temperature prolong performance potential. It offers good resistance to pitting and crevice corrosion in the various chemical conditions. Excellent aqueous corrosion resistance. High oxidation resistance up to 870oC.

Stainless steel phase diagram

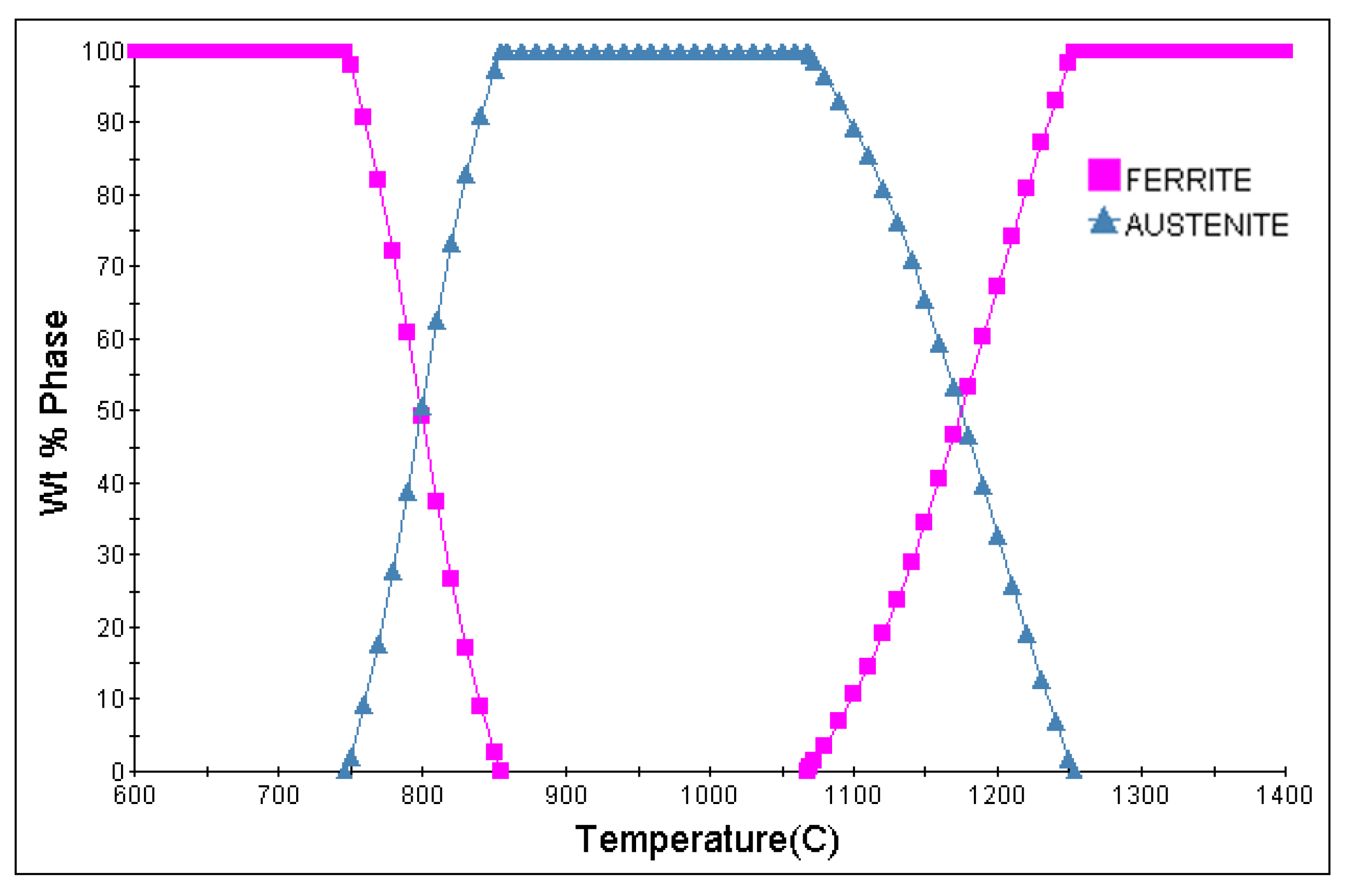

Austenitic Stainless Steels - ASM International austenitic stainless steels is to present 302 as a base. Figure 2 shows one such diagram. Dia-grams such as these treat alloys as an evolution-ary family tree and subtly mislead. Many alloys were pushed toward obsolescence because of advances in processing. For instance, 321 was developed as an alloy in which the detrimental Metastable austenitic stainless steels — Sandvik Materials ... Equilibrium phase diagram of type 18-8 austenitic stainless steel with carbon as a variable. Although it is considered as an austenitic steel it is evident from the diagram that the austenite phase (γ) is not thermodynamically stable at room temperature. However, very few commercial materials are used in their equilibrium state. The steel phase diagram - YouTube No phase diagram is more important to materials scientists than the Fe-C phase diagram because it allows us to explain many of the different types of steels....

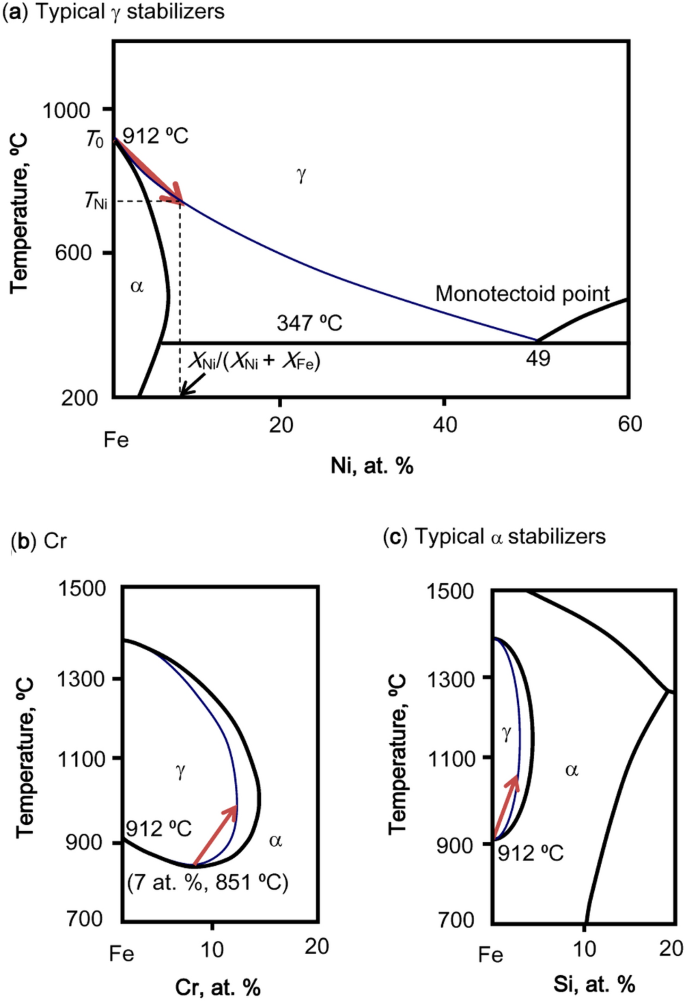

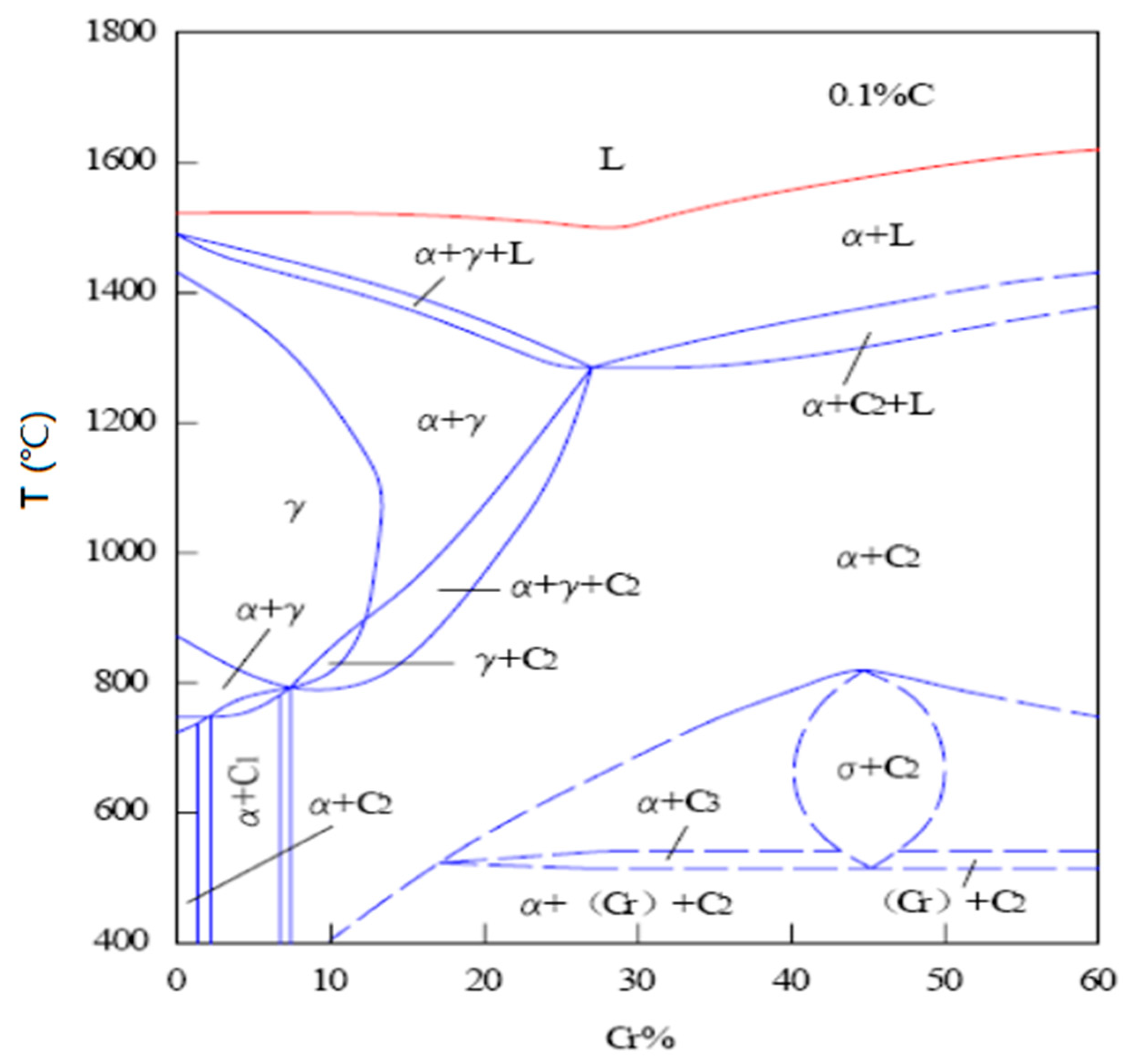

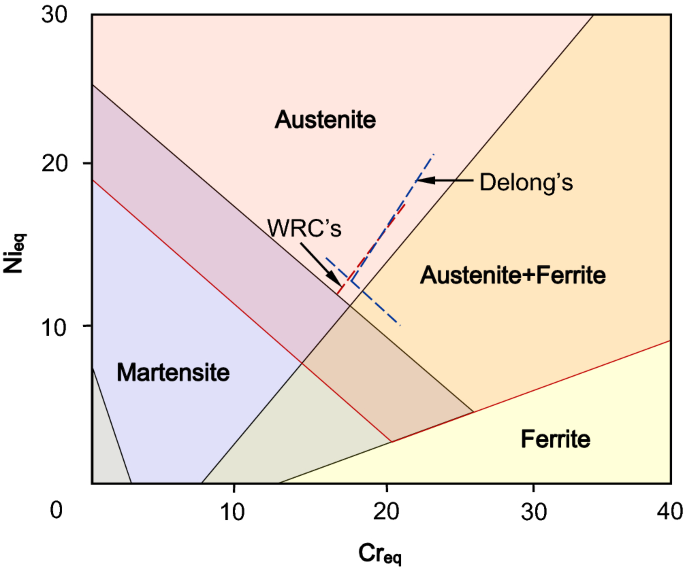

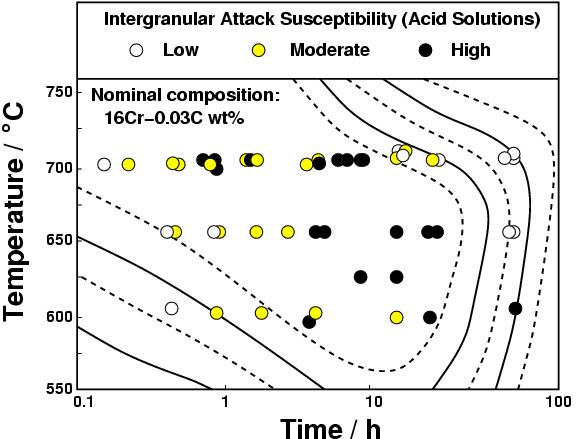

Stainless steel phase diagram. Schaeffler Diagram and its practical uses - www ... What is Schaeffler Diagram? The Schaeffler diagram is an important tool for predicting the constitution of your stainless steel weld deposit. Depending on the alloying elements it contains, the Schaeffler diagram provides information on the various phases (structures) present. Effect of alloying elements in steel and Phase diagram With the addition of the above alloying elements group, four types of changes would possibly occur in the phase diagram including expanding austenite region, contracting austenite region, etc. So, in this article, we will give a brief introduction to steel classification, phase diagram variants, and the effect of alloying elements in steel. Duplex Stainless Steel - Part 1 - TWI Reference to the phase diagrams and CCT curves shows that the duplex stainless steels fall within the area where the production of brittle intermetallic phases is a major risk during welding and heat treatment, markedly reducing both toughness and corrosion resistance. The main culprits are sigma phase, chi phase and 475°C embrittlement. Phase diagrams and microstructure - Stainless steels ... Steel, ever-evolving material, has been the most preeminent of all materials since it can provide wide range of properties that can meet ever-changing requirements. In this course, we explore both fundamental and technical issues related to steels, including iron and steelmaking, microstructure and phase transformation, and their properties and ...

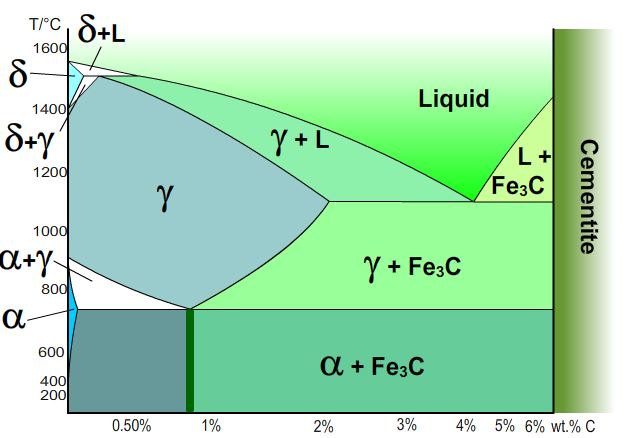

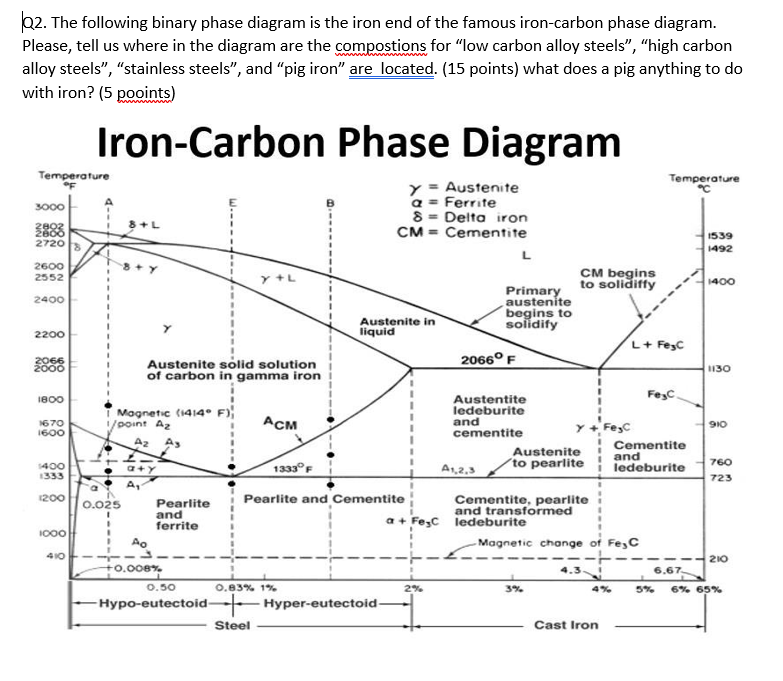

TTT Diagram of steel in Material science - Materials Today The TTT diagram of steel is considered an important transformation diagram for non-equilibrium transformation.There are various non-equilibrium products like Martensite, Bainite which can not be formed by continuous cooling and so can not be explained with phase transformation diagram explained in Martensitic transformation post and Widmanstatten transformation post. Phase Diagram of Steel - Metallurgy for Dummies The diagram shows iron and carbons combined to form Fe-Fe3C at the 6.67%C end of the diagram. The left side of the diagram is pure iron combined with carbon, resulting in steel alloys. Three significant regions can be made relative to the steel portion of the diagram. They are the eutectoid E, the hypoeutectoid A, and the hypereutectoid B. Stainless Steels - University of Cambridge It is evident from Figure 6 (Fe-Cr-C phase diagram) that typical martensitic steels should exhibit ferrite and M 23C 6in equilibrium at for example, 600°C. In practice, this carbide is only found after relatively long ageing. because it is preceded by Intermediate phases in the sequence cementite, M 2X and M 7C 3, leading finally to M 23C 6. Iron-carbon phase diagram - Edelstahl härten Three isothermal reactions are shown in the iron-carbon phase diagram. The line HIB represents a peritectic, the line ECF an eutectic and the left PSK an eutectoid reaction. When steel is heated or cooled, transformations occur on the lines. These are marked by breakpoints. Here are the most important ones:

Sigma Phase Characterization in AISI 316 Stainless Steel Sigma Phase Characterization in AISI 316 Stainless Steel Xiaoli Tang* * Swagelok Company, 29500 Solon Road, Solon, OH 44139, USA Sigma phase (σ) is a chromium/molybdenum-rich intermetallic phase found in the Fe-Cr-Mo system, which occurs when the material dwells or slow cools through the temperature range of 550-1050°C. PDF The Sigma Phase Transformation in Austenitic Stainless Steels which sigma phase is found and often hasten the kinetics of the sigma phase transformation (Refs. 8, 17-20). Howev er, the exact role that these factors play in promoting sigma phase formation is still somewhat obscure. Studies have been conducted recently on the phase stability of Types 308 and 308CRE* stainless steel, both in the as- PDF Fundamentals of the Heat Treating of Steel - ASM International phase diagrams. As a rule, percentages of two principal elements are shown on the horizontal axis of a figure, while temperature variation is shown on the vertical axis. However, the constitutional diagram of a pure ... broadly known as steel. Even in the highly alloyed stainless steels, it is the quite minor constituent Schaeffler Diagram - an overview | ScienceDirect Topics As the stabilizing effect of each element for a given phase is known, it is possible to make use of simple diagrams like the Schaeffler diagram to predict which phase is the stable phase for a given composition of stainless steel (Pickering 1976, Schneider 1960).The Schaeffler diagram (see Fig. 5.1) is prepared by establishing the stable phase (at room temperature) for different compositions ...

PDF Prediction of Solidification Phases in Cr-Ni Stainless ... steel weld metals and applies those methods to LPBF manufactured Cr -Ni stainless steel (S17 - 4. 1). Predictions of the solidification phases in Cr-Ni stainless steel alloys, based on the ratio of the Cr and Ni equivalent, are shown. Incorporating these ratios into the phase solidification diagram helps to predict whether the solidification of ...

Phase Diagram | Metallurgy for Dummies Fe-Mn phase diagram shows which phases are to be expected at equilibrium for different combinations of manganese content and temperature. The melting point of iron and manganese at the pressure of 101325 Pa is 1538 °C and 1246 °C, respectively. ... Stainless Steel Stainless Steel Tubing Steel Service Centers Titanium ...

The steel phase diagram - YouTube No phase diagram is more important to materials scientists than the Fe-C phase diagram because it allows us to explain many of the different types of steels....

Metastable austenitic stainless steels — Sandvik Materials ... Equilibrium phase diagram of type 18-8 austenitic stainless steel with carbon as a variable. Although it is considered as an austenitic steel it is evident from the diagram that the austenite phase (γ) is not thermodynamically stable at room temperature. However, very few commercial materials are used in their equilibrium state.

Austenitic Stainless Steels - ASM International austenitic stainless steels is to present 302 as a base. Figure 2 shows one such diagram. Dia-grams such as these treat alloys as an evolution-ary family tree and subtly mislead. Many alloys were pushed toward obsolescence because of advances in processing. For instance, 321 was developed as an alloy in which the detrimental

![PDF] THE EMPHASIS OF PHASE TRANSFORMATIONS AND ALLOYING ...](https://d3i71xaburhd42.cloudfront.net/4e8dc6d5cbca263f3a5a540cf38b9596c5dcc4db/3-Figure4-1.png)

![Iron-Carbon Phase Diagram Explained [with Graphs]](https://fractory.com/wp-content/uploads/2020/03/Iron-carbon-phase-diagram-explained.jpg.webp)

0 Response to "44 stainless steel phase diagram"

Post a Comment